- Overview

- Inquiry

- Related Products

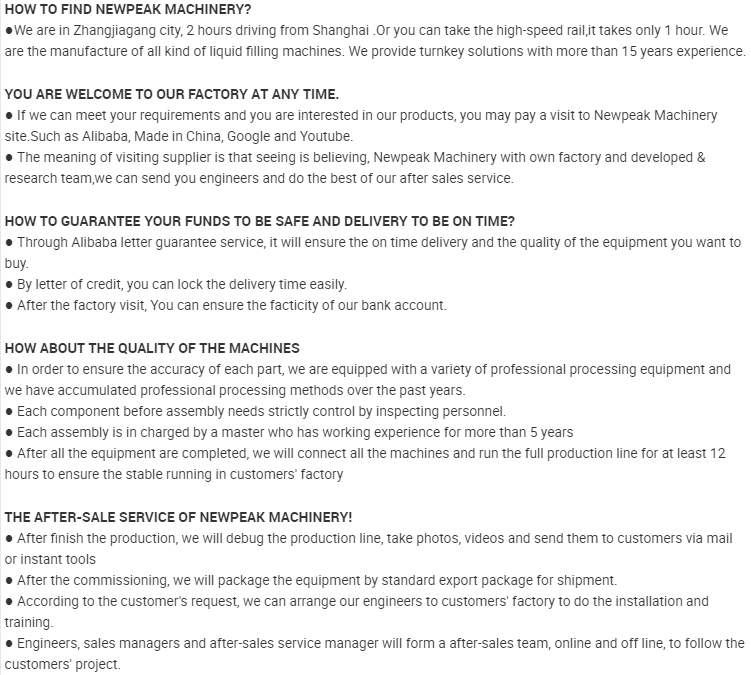

Brand: Newpeak Machinery

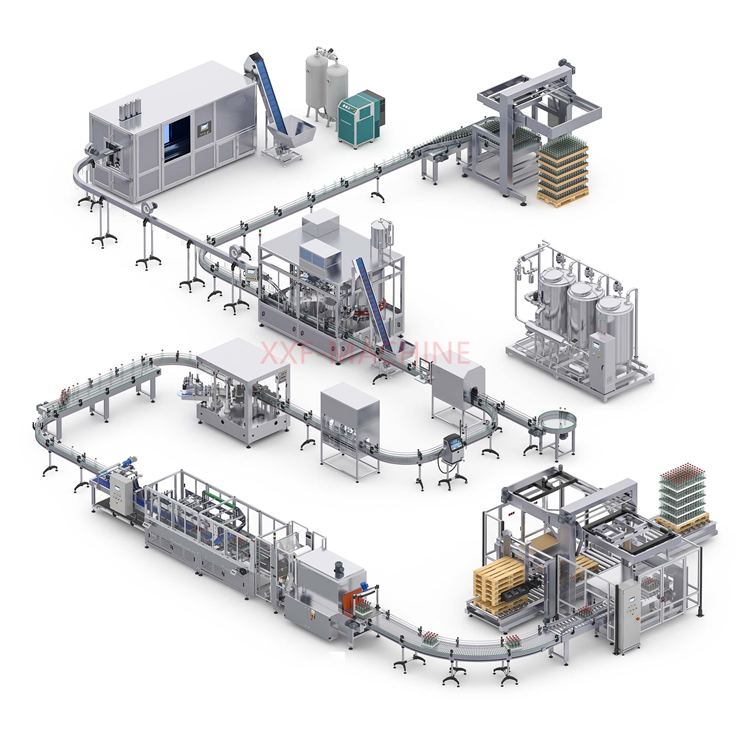

As the name suggests, carbonated beverages are drinks that have carbon dioxide gas dissolved in them. Consumers love the experience of a refreshing, fizzy drink that tickles their taste buds with every sip. And if you're a manufacturer of carbonated beverages, you want to meet this demand in the most efficient way possible. That's why you need the Carbonated Beverage Production Line.

Whether you are looking to make soft drink, tonic water, or sparkling water, this has you covered.

Consists of various devices, each featuring its unique functionality. This line supplies a complete means to fix your carbonated drink manufacturing needs from blending the components to bottling the last item.

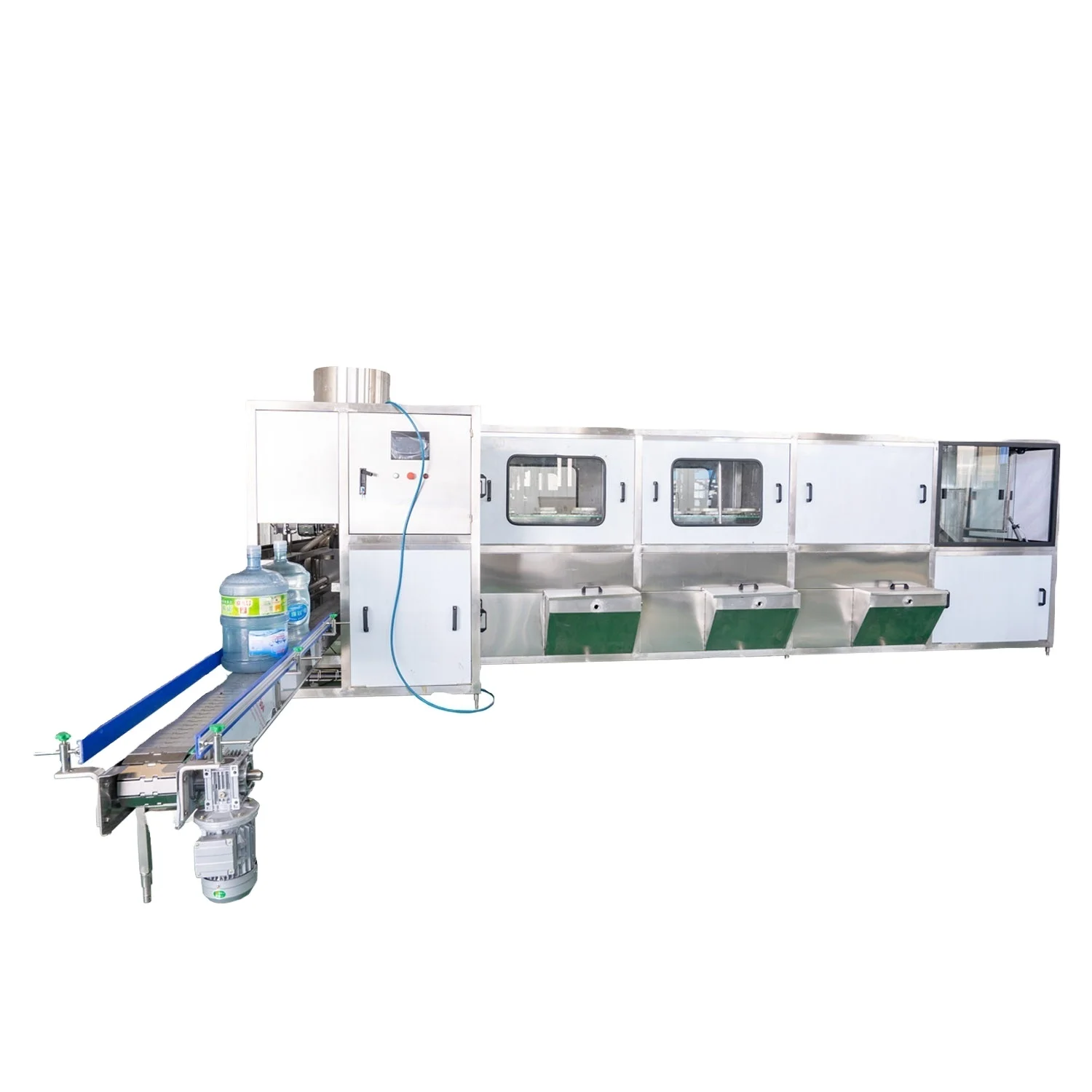

The equipment that is first the line may be the water therapy system. This technique purifies water that'll be found in the manufacturing procedure, making sure it fulfills the product quality that's needed is. Water therapy system is designed for various water sources, including well water, springtime water, and water that is municipal.

Next the blending tank, where in fact the components are combined. The blending tank features a homogenizer that ensures that the components are blended completely, making a flavor that is constant texture. The blending tank comes with a home heating that heats the combination, helping break down the sugar as well as other components.

After the combination is prepared, it really is used in the carbonating and system that is combining. This is how the skin tightening and fuel is added, producing the characteristic flavor that is fizzy texture for the drink. The carbonating and blending system also offers a sterilization function, ensuring that the merchandise that is last safe for usage.

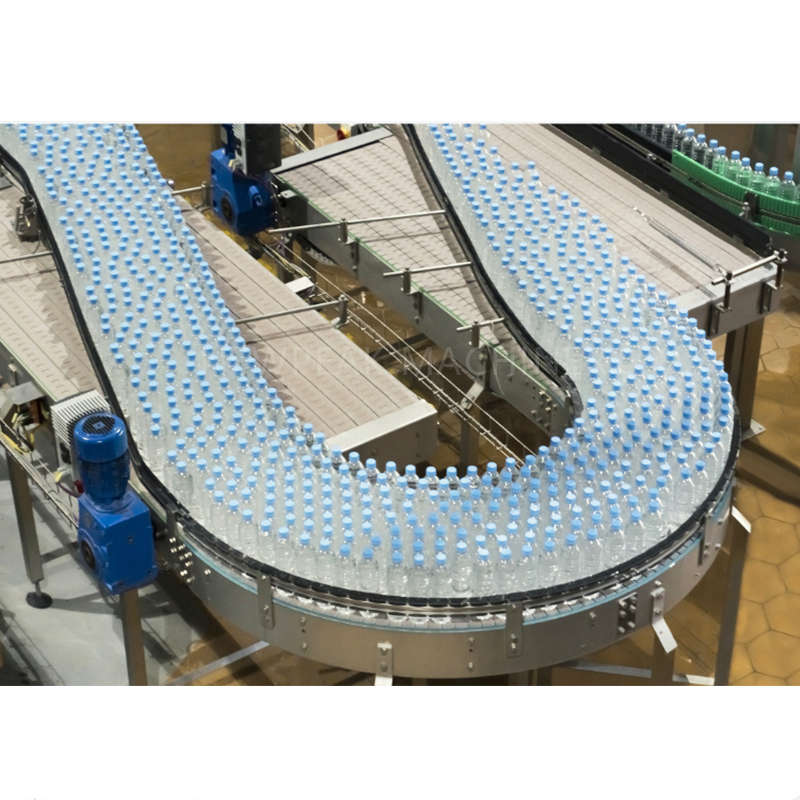

After carbonation, the combination is utilized in the stuffing and device that is capping. This device fills the containers because of the drink that is carbonated seals them firmly with caps. The stuffing and device that is capping a high-speed manufacturing capability and may manage various container shapes and sizes.

Last the line could be the labeling machine, which could use labels to your containers with a high accuracy. The labeling device can use front and labels being straight back in addition to wrap-around labels, making sure your brand name's logo design as well as other info is noticeable to clients.

Choose the Carbonated Beverage Production Line and give your customers the best carbonated beverage experience.

Technical parameter : carbonated beverage production line |

||||||||||||

Model |

DCGF14-12-5 |

DCGF16-16-6 |

DCGF18-18-6 |

DCGF24-24-8 |

DCGF32-32-10 |

DCGF40-40-12 |

||||||

Capacity(for 500ml) |

2000-3000 |

3000-4000 |

4000-5000 |

8000-9000 |

11000-12000 |

13000-15000 |

||||||

Suitable bottle shapes |

circular or square |

|||||||||||

Bottle diameter(mm) |

Dia50-Dia115mm |

|||||||||||

Bottle height (mm) |

160-320mm |

|||||||||||

Compressor air |

0.3-0.7Mpa |

|||||||||||

Washing meidium |

Aseptic water |

|||||||||||

Rinsing pressure |

>0.06Mpa<0.2mpa<>

|

|||||||||||

Application |

carbonated beverage production line |

|||||||||||

Total power (KW) |

4.4kw |

4.8kw |

5.2kw |

6.2kw |

7.5kw |

8.2kw |

||||||

Overall dimensions |

2.5*1.9m |

2.7*1.9m |

2.8*2.15m |

3.1*2.5m |

3.8*2.8m |

4.5*3.3m |

||||||

Height |

2.3m |

2.5m |

2.5m |

2.5m |

2.5m |

2.6m |

||||||

Weight(kg) |

3000kg |

4000kg |

4500kg |

6000kg |

8500kg |

10000kg |

||||||

water treatment

Beverage Mixing System

---Friendly HMI with easy switch for multi-languages. ---The filling valve is designed with the tidy and safe valve body, the material quality can be fully guaranteed. ---Advanced electronic isobaric filling valves to be used for a variety of materials, higher filling temperatures, higher filling accuracy, and lower carbon dioxide consumption can be achieved. ---The unique patented technology for bottle rinsing, no bottle without flushing at fixed stations, saving water for customers ---Similar capping technology from Krones, Germany, each torque balance, high efficiency

Labeling Machine

Bottle Packing System

Bottle Blowing System

machine,including air compressor system and water cooling system .

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ