- Overview

- Inquiry

- Related Products

New peak Machinery

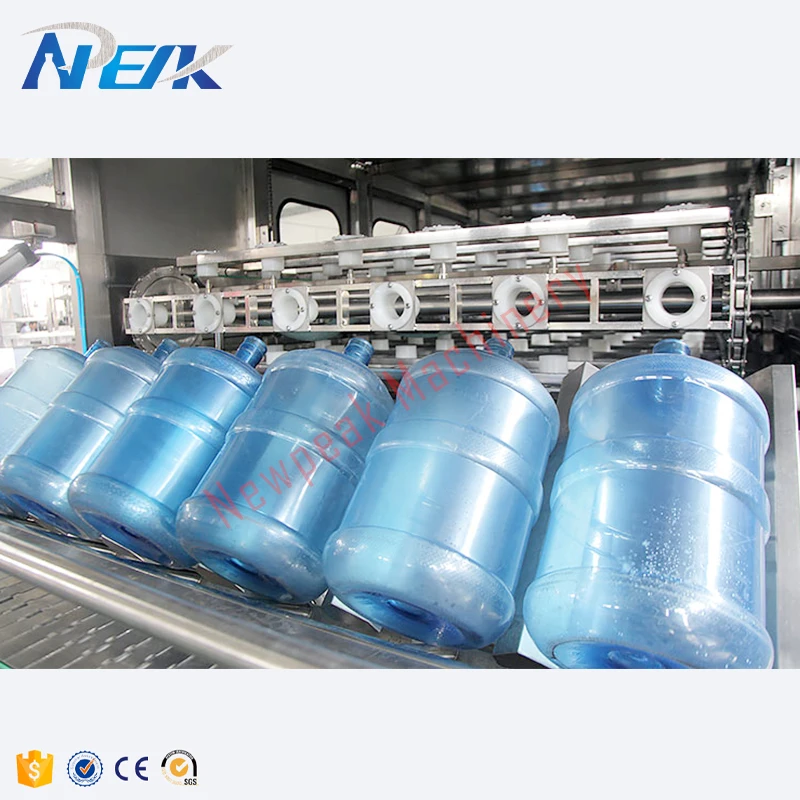

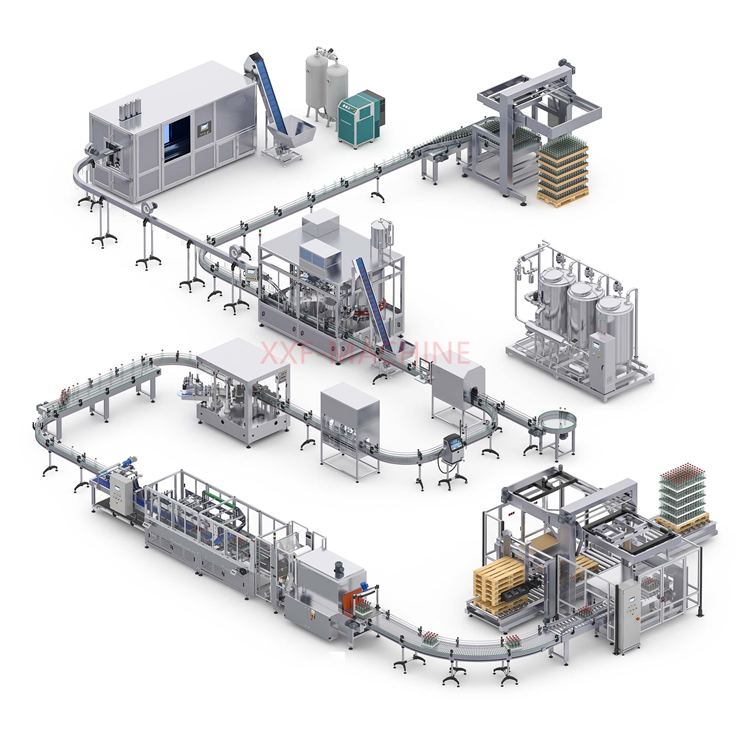

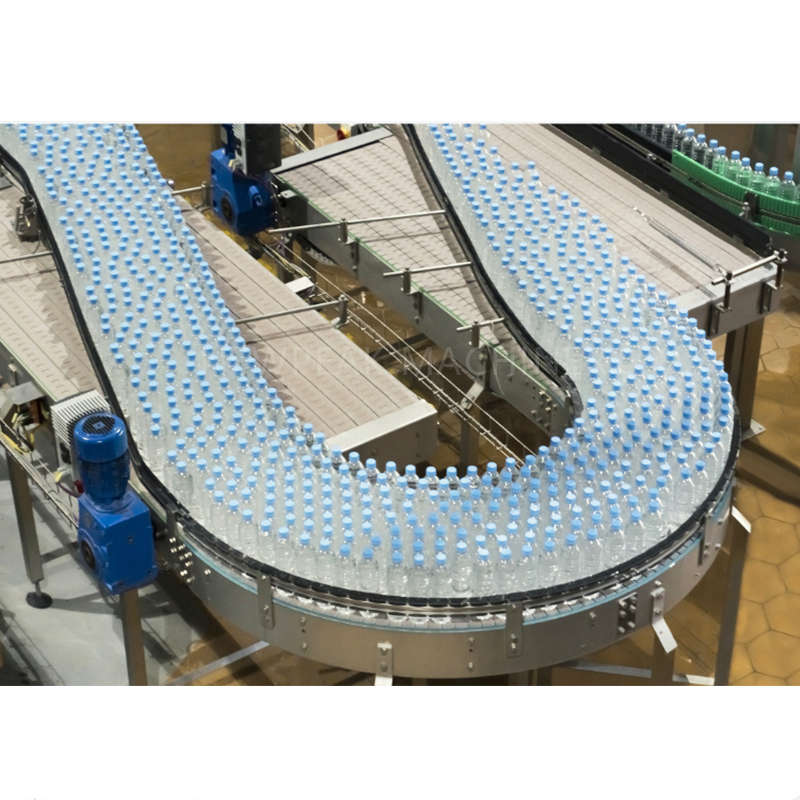

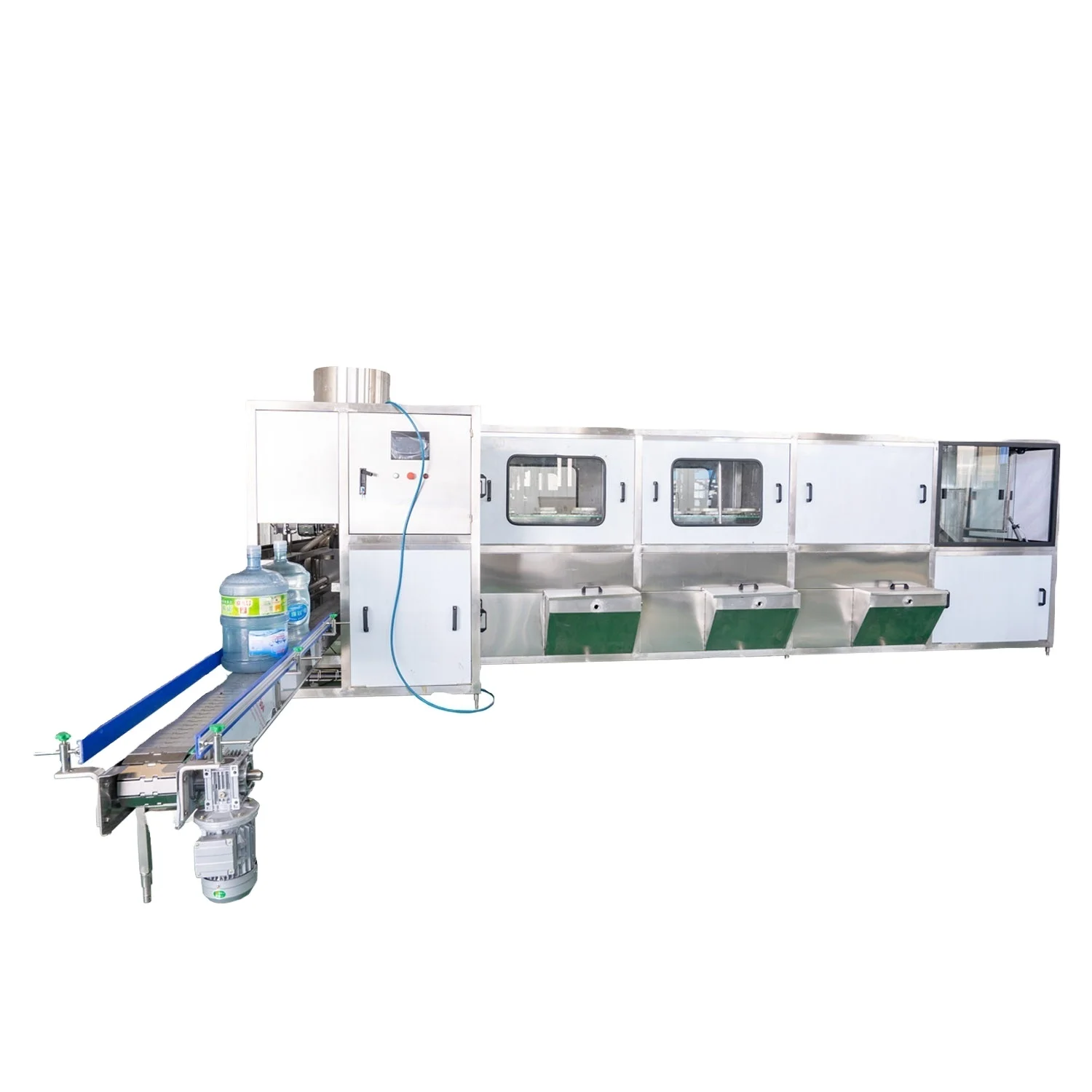

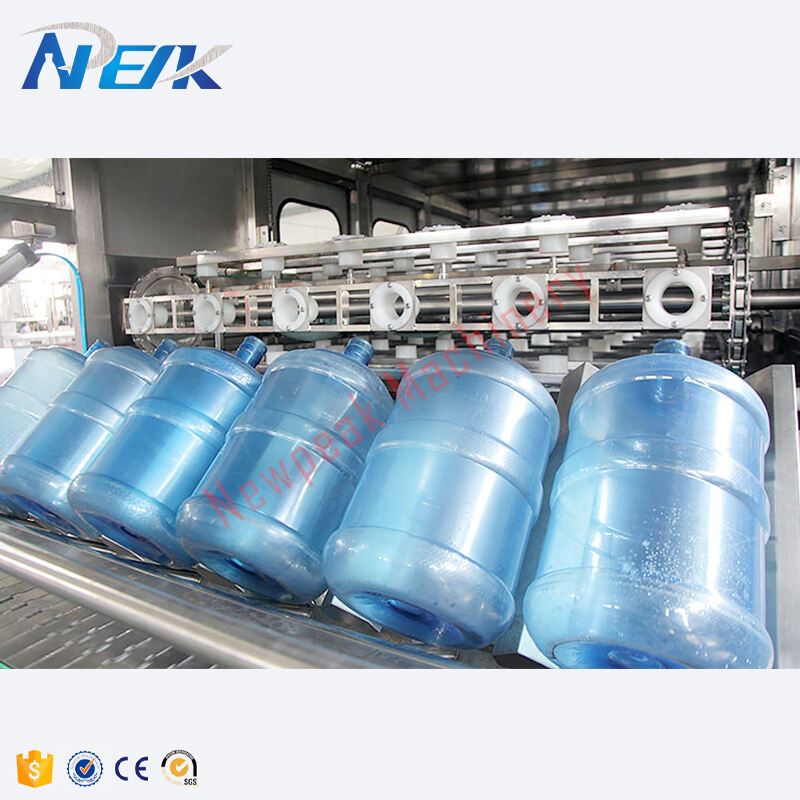

19 liters water that is bottled machine is an equipment that is top-of-the-line filling large sized water containers quickly and accurately. This equipment that is high-quality effortlessly fill up to 200 bottles 60 minutes, making sure your production process are able to keep up with need.

Designed with simplicity of efficiency and use in your mind, this product is perfect for water producing businesses of all sizes. The New peak Machinery 19 liters water in bottles filling machine are designed for a wide range of bottle sizes and shapes, making this a versatile addition to its sturdy and durable build to your manufacturing line.

Utilizing the technology this is certainly latest, this machine features an enhanced control system that lets you adjust all settings effortlessly due to the touch of the switch. This can allow it to be easy for also novice users to utilize the equipment with ease and precision.

The product is made with most of the finest materials for long-lasting durability and gratification. These device’s outside is manufactured out of high-quality steel this is certainly stainless that will maybe not break or corrode with time like other materials may, which makes it perfect for long-term use. The interior related to device is designed for easy upkeep and cleansing, making sure it stays clean and hygienic when it comes to customers.

This system was engineered to generally meet with the highest criteria of effectiveness and safety. The gear comes with high level security features that help prevent accidents and then make sure your staff stay safe while operating the apparatus.

The New peak Machinery 19 liters water that is bottled machine makes it possible to reduce waste while increasing earnings by optimizing for accuracy and effectiveness. By minimizing spillage and residues, you can spend less on materials and manufacturing costs.

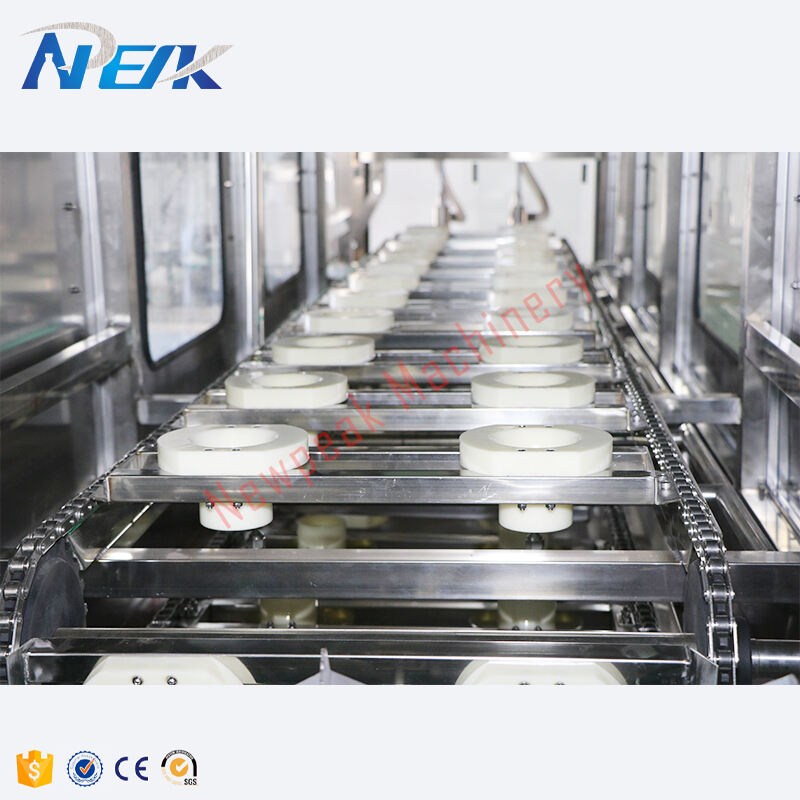

Washing Parts

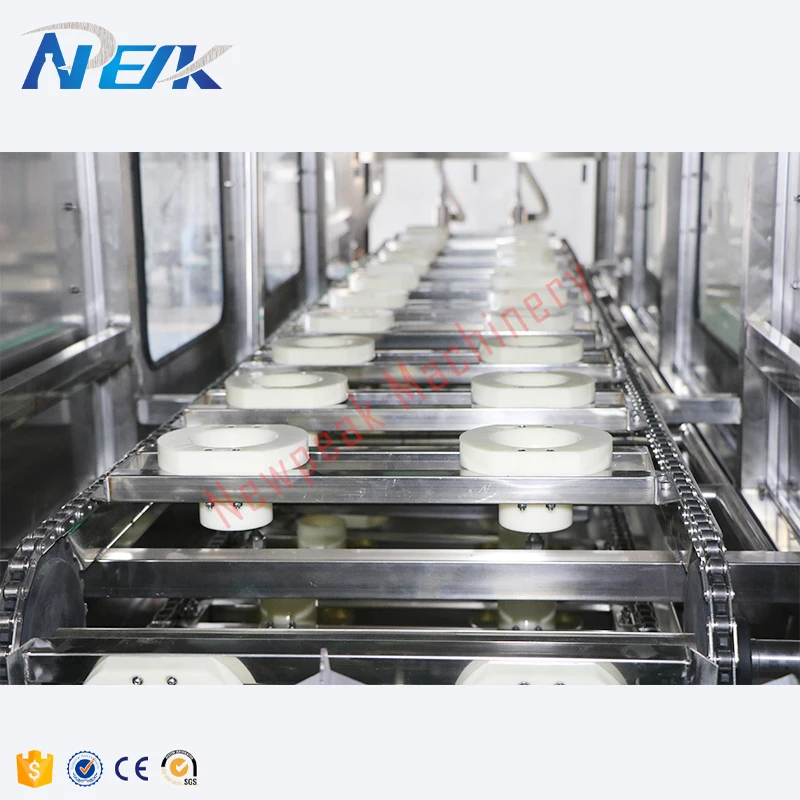

- Into bottle way is air conveyor direct connection with bottle dial.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

2/Nozzle can insert into 10-15cm of the barrel in order to rinse little impurities down. Rinsing pump is separately controlled by different magnetic valves. Pump only work when there is barrel on that. It can avoid the mixture of different cleaning fluid.

2/Machine is equipped with Cap Sterilization system, which is 1.2m. The system make products more clean and safe by using sterilization and finished water.

3/Customers can choose to equip ABB/SEW motor, GRUNDFOS water pump, FESTO pneumatic component.

Model |

QGF-100 |

QGF-300 |

QGF-450 |

QGF-600 |

QGF-900 |

QGF-1200 |

Filling heads |

1 |

3 |

4 |

4 |

6 |

8 |

Volume |

18.9 L |

|||||

Barrel size |

Φ270*490mm |

|||||

Capacity |

100bph |

300bph |

450bph |

600bph |

900bph |

1200bph |

Gas pressure |

0.4-0.6mpa |

0.4-0.6mpa |

0.4-0.6mpa |

0.6mpa |

0.6mpa |

0.6mpa |

Gas consumption |

0.379(m3/min) |

0.6(m3/min) |

0.8(m3/min) |

1(m3/min) |

1.5(m3/min) |

1.8(m3/min) |

Motor power |

1.38kw |

3.8kw |

3.8kw |

7.5kw |

9.75kw |

13.5kw |

Rated voltage |

380V/50Hz |

380V/50Hz |

380V/50Hz |

380V/50Hz |

380V/50Hz |

380V/50Hz |

NEWPEAK MACHINERY - Alibaba Verified Packaging Machinery Supplier - CE SGS

HOW TO FIND NEWPEAK MACHINERY?

● Search Alibaba, Made in China, Google, YouTube and find suppliers and manufacture and not traders. ● Visit exhibition in different countries. ● Send NEWPEAK MACHINERY and request and tell your basic inquiry. ● NEWPEAK MACHINERY sales manager will reply you in short time and add instant chatting tool.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fulfill your request and you interested in our products, you may pay a visit to NEWPEAK MACHINERY site.

● The meaning of visiting supplier, because seeing is believing, NEWPEAK MACHINERY with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE NEWPEAK MACHINERY HOW TO ENSURE THE QUALITY?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers factory.

THE AFTER-SALE SERVICE OF NEWPEAK MACHINERY?

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form an after-sales team, online and off line, to follow the customers' project.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ