- Overview

- Inquiry

- Related Products

New peak Machinery

Enthusiastic about a simple yet effective and way is fill that dependable bottles? Look no further than the Automatic Glass Bottled Filling Machine from New peak Machinery.

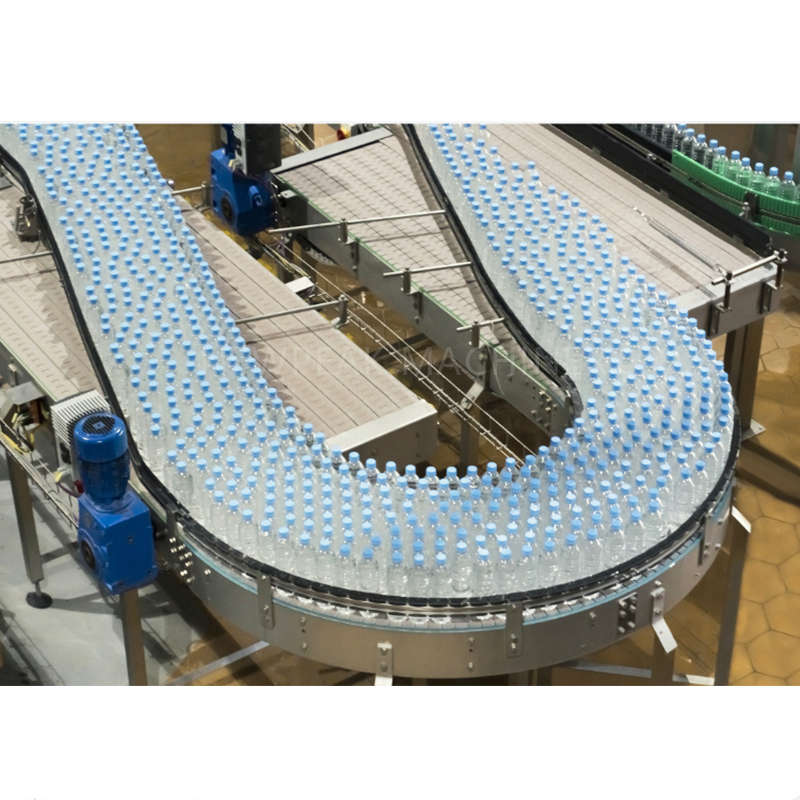

This advanced machine was created with simplicity and efficiency at heart, offering a selection of features and benefits making it a must-have for virtually any busy operation this is certainly bottling.

One of several key advantages of the New peak Machinery Automatic Glass Bottled Filling Machine is it’s fully operation this is certainly automated. The unit can automatically fill cup bottles of numerous size and shapes, without the need for manual intervention with advanced sensors and controls. This might save time is valuable labor expenses, letting you consider other areas of your company.

The Automatic Glass Bottled Filling Machine now offers a known level this is certainly most of and precision. With adjustable rate that is filling amount settings, you are able to make sure each container is filled into the exact requirements you're looking for. This is certainly especially essential for keeping product persistence and quality.

In addition, the New peak Machinery Automatic Glass Bottled Filling Machine is produced with hygiene and security in your mind. All parts that come into connection with all the liquid are made of top-quality steel that is stainless that will be easy to clean and resistant to corrosion. The apparatus also contains a selection of security precautions, including shut-off this is certainly automatic the big event regarding the malfunction or emergency.

Other helpful features of the New peak Machinery Automatic Glass Bottled Filling Machine include its size is certainly compact and that easy-to-use. This revolutionary product was designed to be structured and space-saving, which makes it an ideal choice for smaller operations or facilities with restricted space on the floor despite its effective abilities.

Capacity (500ml bottles):2000-20000ml

Suitable bottle shapes:PET circular or square

Bottle diameter (mm):φ50-115mm

Bottle height (mm):160-320mm

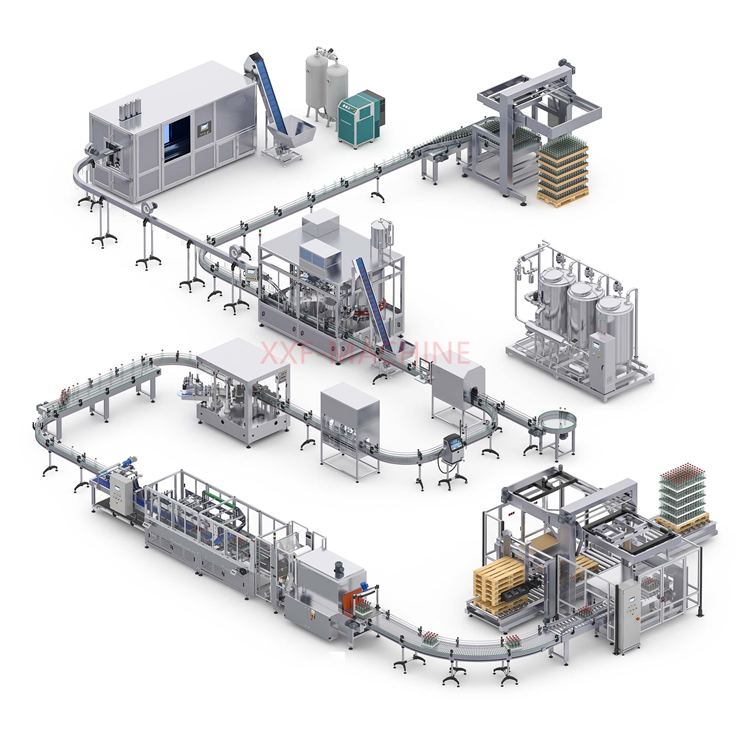

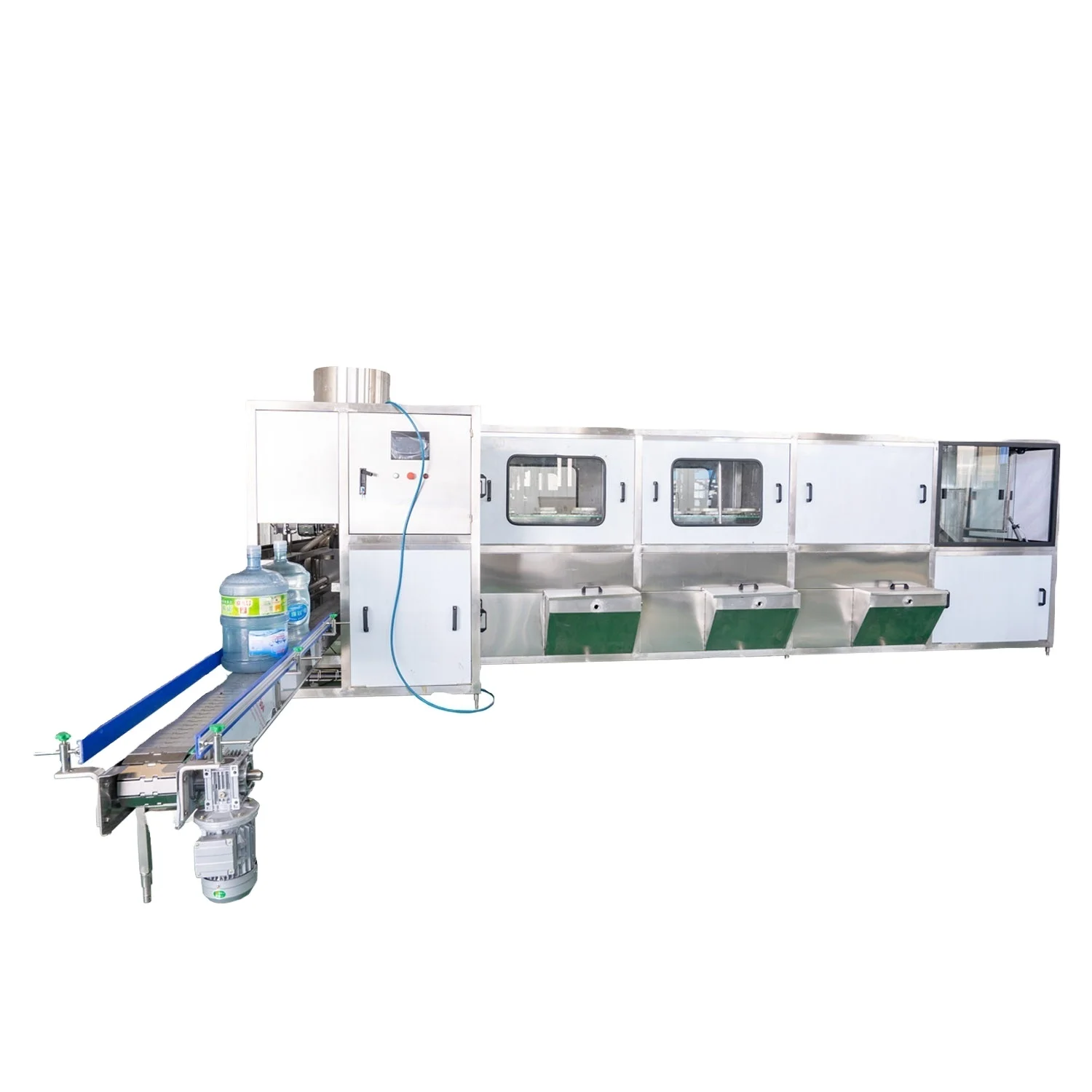

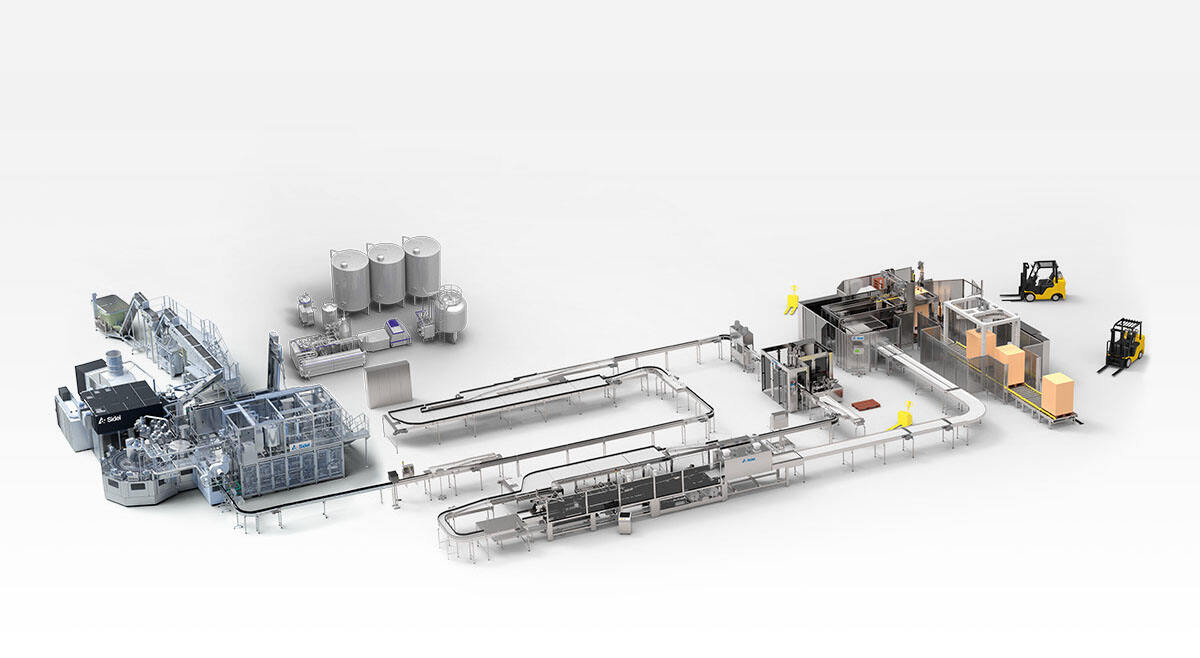

This pet bottle drinking water pulp filling machinery has washer, filler, and capper three functions in one body, total process is automatic.

Automatic 500ml Bottle Bottled Water packing and Filling Machine

It is suitable for high temperature resistant PET/Glass/Aluminum bottled drinking water filling. It applies advanced micro-pressure gravity type filling principle, with perfect recirculation system, also can reach separately gas return, without contacting with material, and avoid secondary pollution and oxygen. It is made of high quality SUS304 stainless steel.

Special design for washing part

Special design for capping part

Main Features.

Model |

RCGF8-8-4 |

RCGF14-12-5 |

RCGF18-18-6 |

RCGF24-24-8 |

Production Capacity

|

2000BPH~2500BPH |

3000BPH~3500BPH |

6000BPH~7000BPH |

8000BPH~10000BPH |

Bottle height |

330mm |

|||

Bottle diametar |

50~100mm |

|||

Bottle volume |

0.2~2L |

|||

Rinsing pressure |

0.2~0.3Mpa

|

|||

Rinsing water consumption

|

0.5T/H |

|||

Filling precision |

±2~3% |

|||

Power |

3ph,380V/50Hz,1.5Kw |

3ph,380V/50Hz,1.5Kw |

3ph,380V/50Hz,2Kw |

3ph,380V/50Hz,3Kw |

NEWPEAK MACHINERY - Alibaba Verified Packaging Machinery Supplier - CE SGS

HOW TO FIND NEWPEAK MACHINERY?

● Search Alibaba, Made in China, Google, YouTube and find suppliers and manufacture and not traders. ● Visit exhibition in different countries. ● Send NEWPEAK MACHINERY and request and tell your basic inquiry. ● NEWPEAK MACHINERY sales manager will reply you in short time and add instant chatting tool.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fulfill your request and you interested in our products, you may pay a visit to NEWPEAK MACHINERY site.

● The meaning of visiting supplier, because seeing is believing, NEWPEAK MACHINERY with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE NEWPEAK MACHINERY HOW TO ENSURE THE QUALITY?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers factory.

THE AFTER-SALE SERVICE OF NEWPEAK MACHINERY?

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form an after-sales team, online and off line, to follow the customers' project.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ