- Overview

- Inquiry

- Related Products

Brand: Newpeak Machinery

Automating your water bottle production process has not been simpler with Automatic Water Bottle Production Line. This system that is innovative built to simplify your bottle operations that are manufacturing make certain you're in a position to produce top-notch bottles effortlessly and cost-effectively.

The Automatic liquid Bottle Production Line is made to control a variety this is certainly wide of manufacturing needs. This system that is whether you want to create little or big containers versatile you covered. Its procedures being automatic you may produce containers which can be perfect, without the need for human being intervention.

One of the standout top popular features of the Automatic Water Bottle Production Line is its energy to simply work at high rates without compromising on quality. This product that is revolutionary create bulk levels of containers inside a whilst this is certainly little having a manufacturing capacity for 5000-8000 containers each hour. This might allow it to be an alternative solution this is certainly companies that are perfect to produce containers in big volumes.

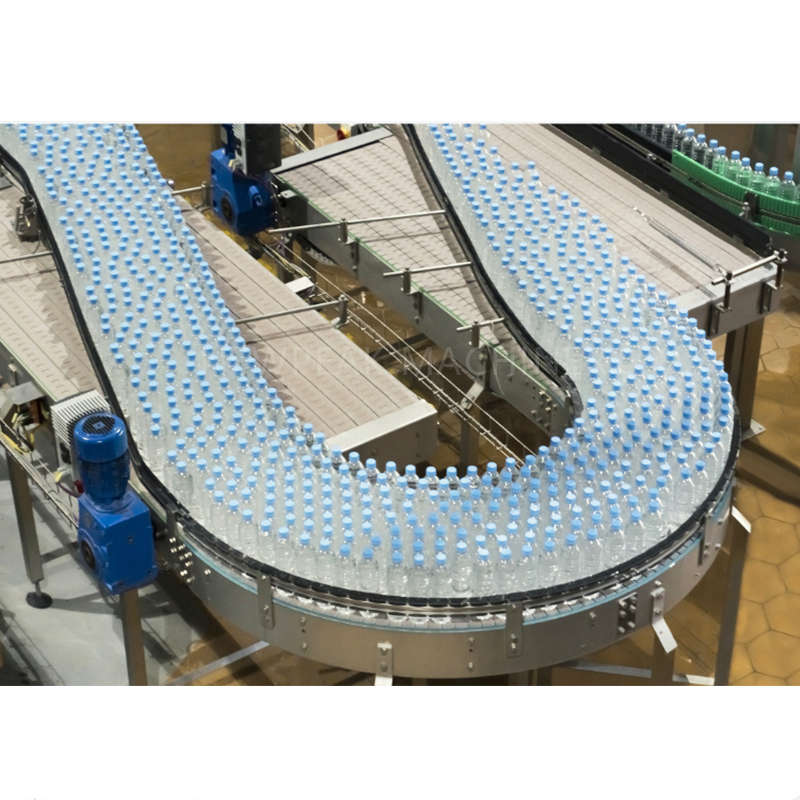

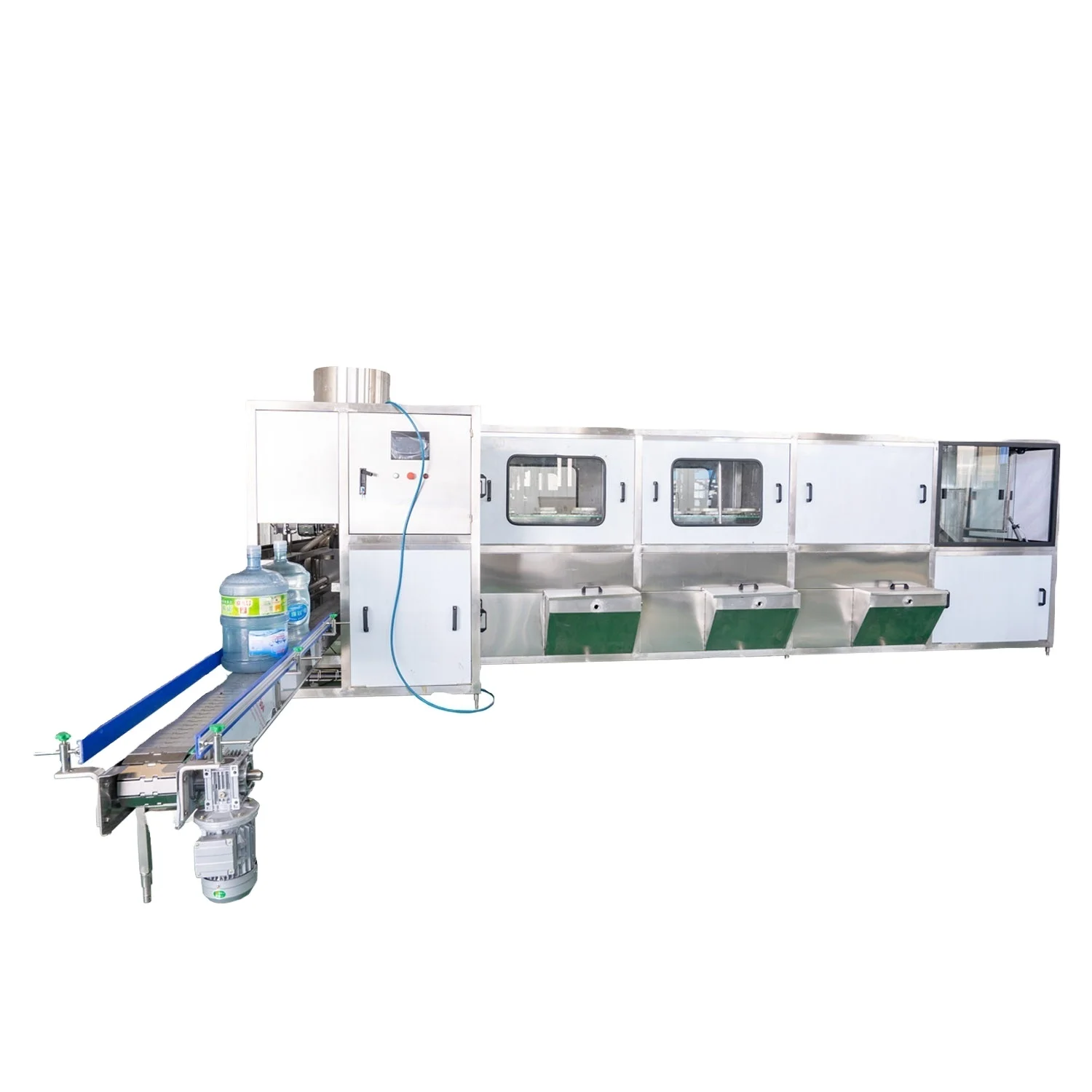

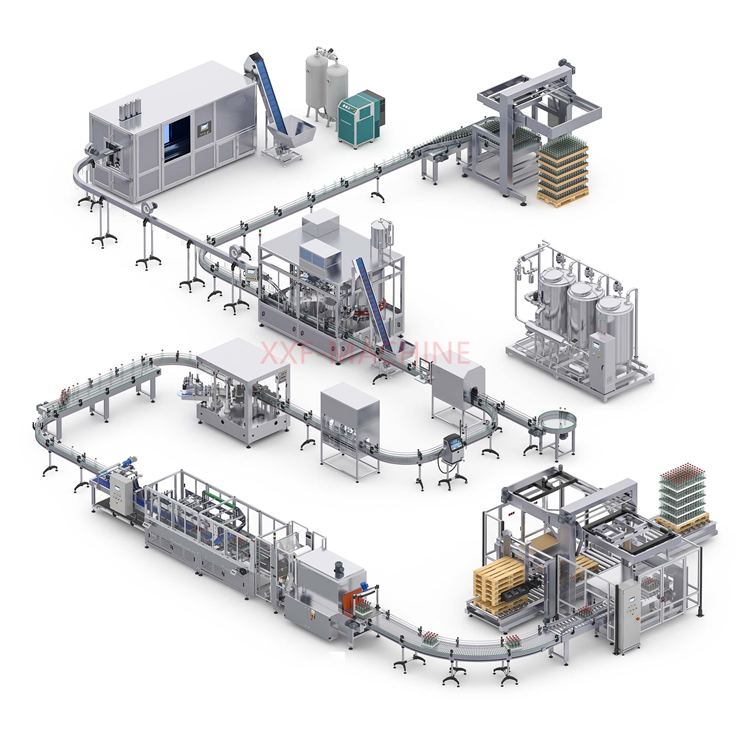

The manufacturing line features elements that may together vary come to present a smooth and production procedure this is certainly seamless. These include a preform injection molding system, bottle system this is certainly blowing too as a system that is filling is automated. All those elements were designed to make use of harmony so as to make containers and also this may be meet this is certainly criteria that are top-notch.

The Automatic Water Bottle Production Line normally beautifully created using effectiveness in your mind. It really is loaded with energy-efficient technologies that assistance to lessen your manufacturing expenses and minimize power wastage. This, alongside its procedures being automated really helps you to lower your overheads while upping your efficiency.

The Automatic Water Bottle Production Line could be an easy task to run along with its effectiveness and price. It boils down insurance firms a control this is certainly user-friendly that allows one to adjust these devices' settings and monitor its performance. Furthermore, its design this is certainly means that are compact for organizations with restricted living area it could match small areas, making.

Using this production line, you can streamline your production processes, raise your efficiency, and produce bottles that are top-notch meet industry standards.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

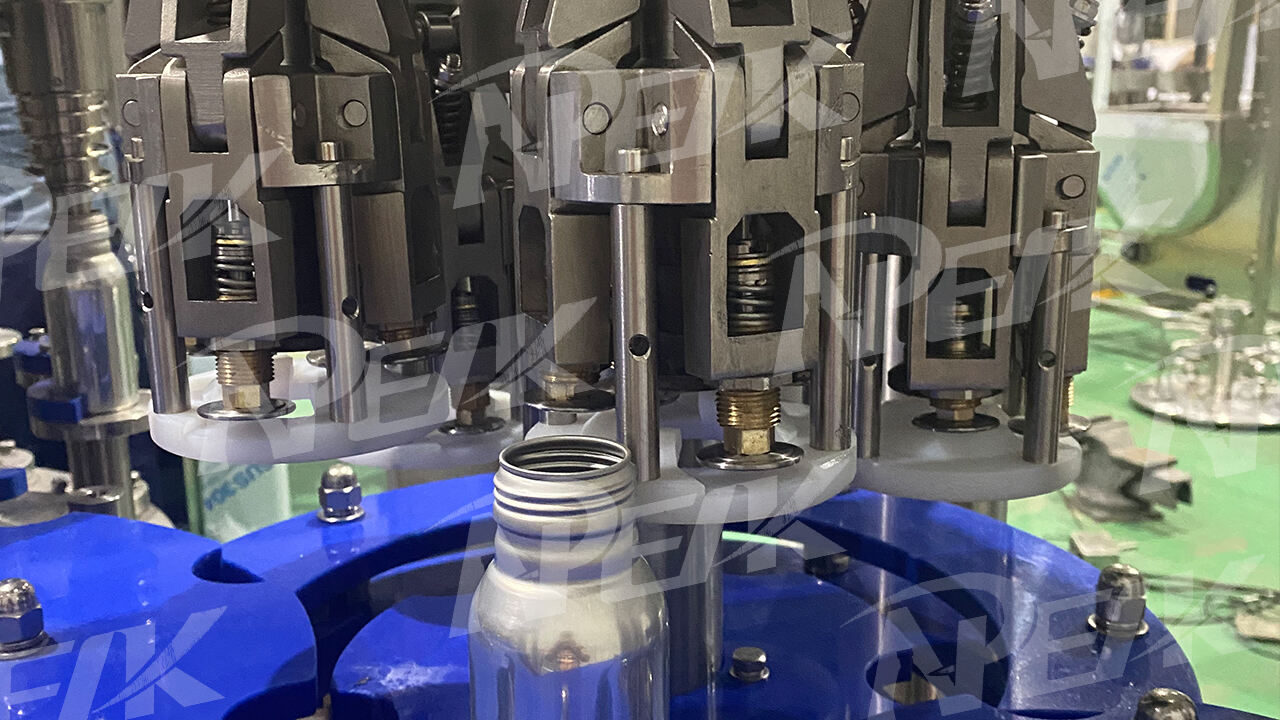

capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

Main Features.

2. To change bottle shape, the operator only needs to replace the star-wheel, inlet bottle screw and arc guide plate.

3. The parts contacting media are made from stainless steel and have no process blind angles to enable easy cleaning.

4. High speed filling valve, guarantees liquid has precise level and no waste is incurred.

5.The capping head applies a constant magnetic torque device to secure capping quality and prevent damage to the bottle cap.

6.The control system has the function of control producing speed, cap shortage detection, bottle block auto stop and production

counting.

7.The bottled water filling machine applies a highly effective cap arranging system that has complete self control and protective device.

8 .The machine is equipped with a complete overload protection device that can secure equipment and the operator

effectively.

9. The machine's operation is controlled by an advanced touch-screen that can fulfill human-machine communication.

Model |

RCGF8-8-4 |

RCGF14-12-5 |

RCGF18-18-6 |

RCGF24-24-8 |

|||

Production Capacity

|

2000BPH |

3500BOH |

8000BPH |

11000BPH~14000BPH |

|||

Bottle height |

330mm |

||||||

Bottle diametar |

50~100mm |

||||||

Bottle volume |

0.2~2L |

||||||

Rinsing pressure |

0.2~0.3Mpa

|

||||||

Rinsing water consumption

|

0.5T/H |

0.15-0.35 |

0.15-0.35 |

0.15-0.35 |

|||

Filling precision |

±2~3% |

0.2-0.25 |

0.2-0.25 |

0.2-0.25 |

|||

Power |

3ph,380V/50Hz,1.5Kw |

3ph,380V/50Hz,1.5Kw |

3ph,380V/50Hz,2Kw |

3ph,380V/50Hz,3Kw |

|||

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ