- Overview

- Inquiry

- Related Products

Newpeak Machinery

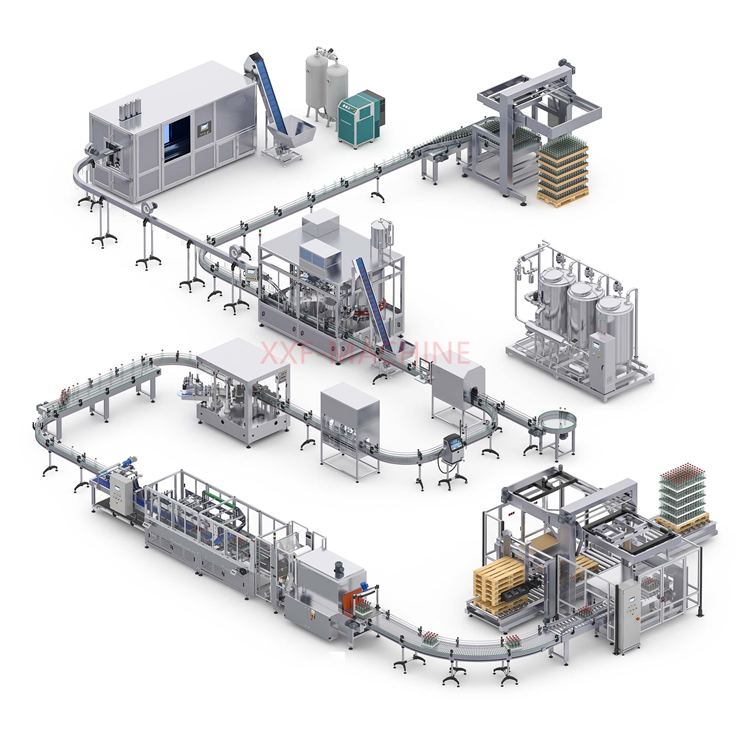

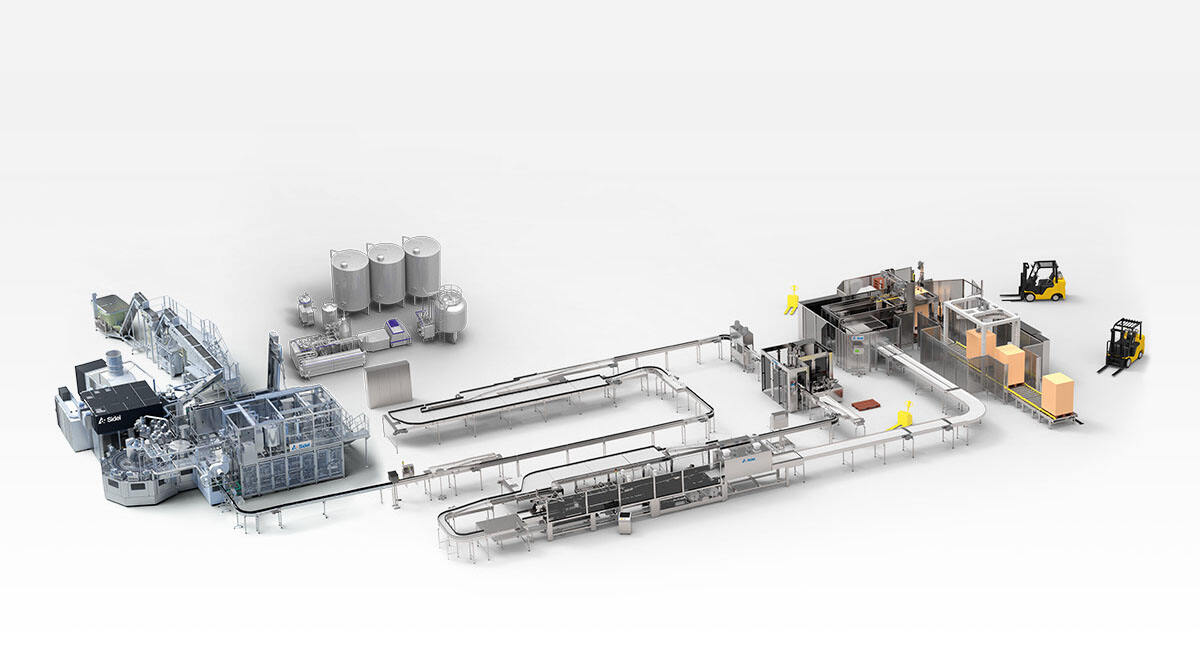

Proud to present our Purified Drinking Water Production Line - a state-of-the-art water purification system that delivers the purest, most refreshing drinking water.

Comprised of higher level water therapy gear, including osmosis is reverse, pre-treatment system, fine filtration, and ozone generator. These components come together to remove impurities such as for example germs, viruses, sediment, and chlorine, making sure water. We create is of this quality is greatest.

The Purified Drinking Water Production Line was created with effectiveness, automation, and security in your mind. Our manufacturing line is completely automatic, reducing the necessity for handbook work and minimizing the possibility of people’s mistake. The procedure is entire managed by way of a main computer system, which monitors water quality, regulates water movement, and adjusts purification parameters in real-time.

Along with our purification that is advanced technology our manufacturing line normally fashioned with sustainability and cost-effectiveness at heart. Our reverse osmosis system works on the membrane layer that is low-energy requires less electricity than many other water purification systems, decreasing our carbon impact and reducing our power expenses. Our bodies additionally includes a water product is recycling decreases water waste, making our manufacturing procedure more eco-friendly and economical.

We recognize that purified drinking tap water is just a resource is critical must certainly be available to all. That is why our manufacturing line is effective at creating as much as 10,000 liters of purified water per hour, rendering it well suited for large-scale applications such as for instance municipal water systems or bottling is commercial. The Purified Drinking Water Production Line may be the perfect solution whether you are looking to give you clean drinking tap water for the community or even to create top-notch water in bottles.

Our production line is easy to install and maintain, allowing for hassle-free operation and a low total cost of ownership. We also offer on-site training and customer support to ensure that your production line is running smoothly. With our Purified Drinking Water Production Line, you can be confident that you're providing your customers with the purest, most refreshing drinking water possible.

Contact us today to learn more about our products and services.

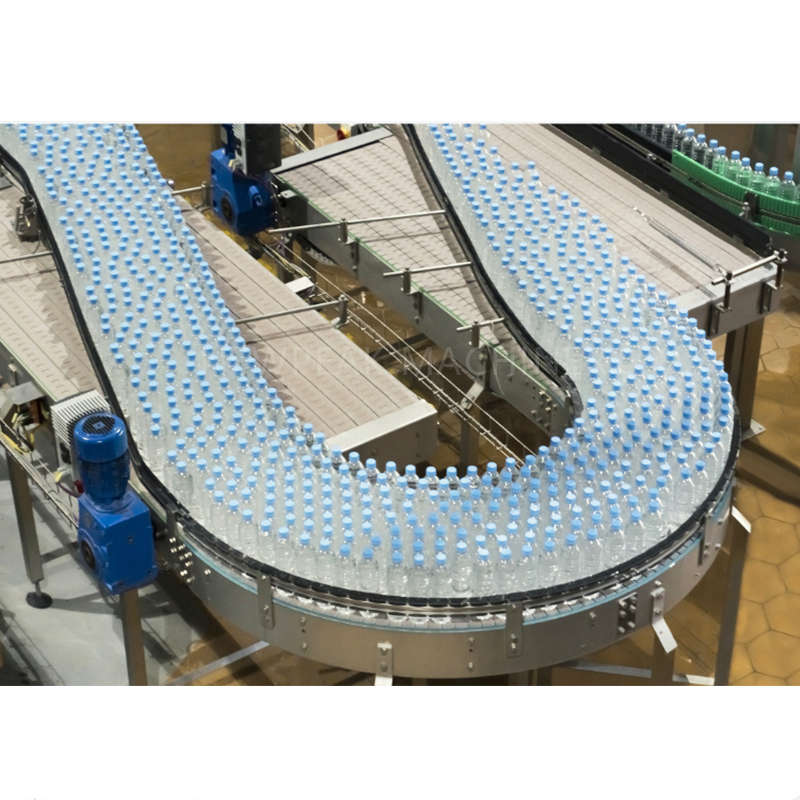

12000bph Water Filling Machine Full Line Bottling For Purified Pure Mineral Spring Drinking Water Production

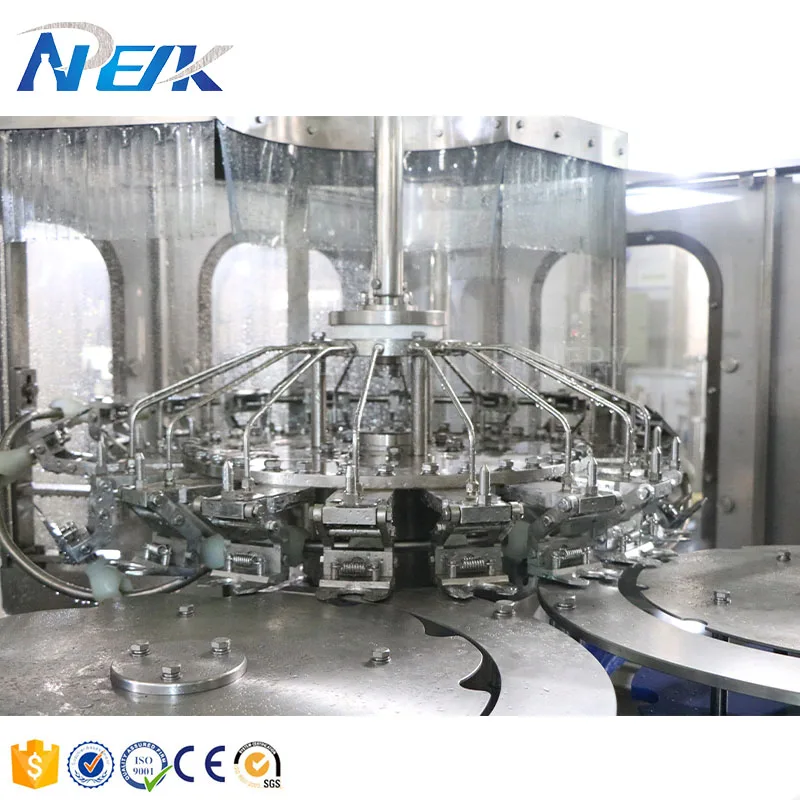

This pet bottle drinking water pulp filling machinery has washer, filler, and capper three functions in one body, total process is automatic.

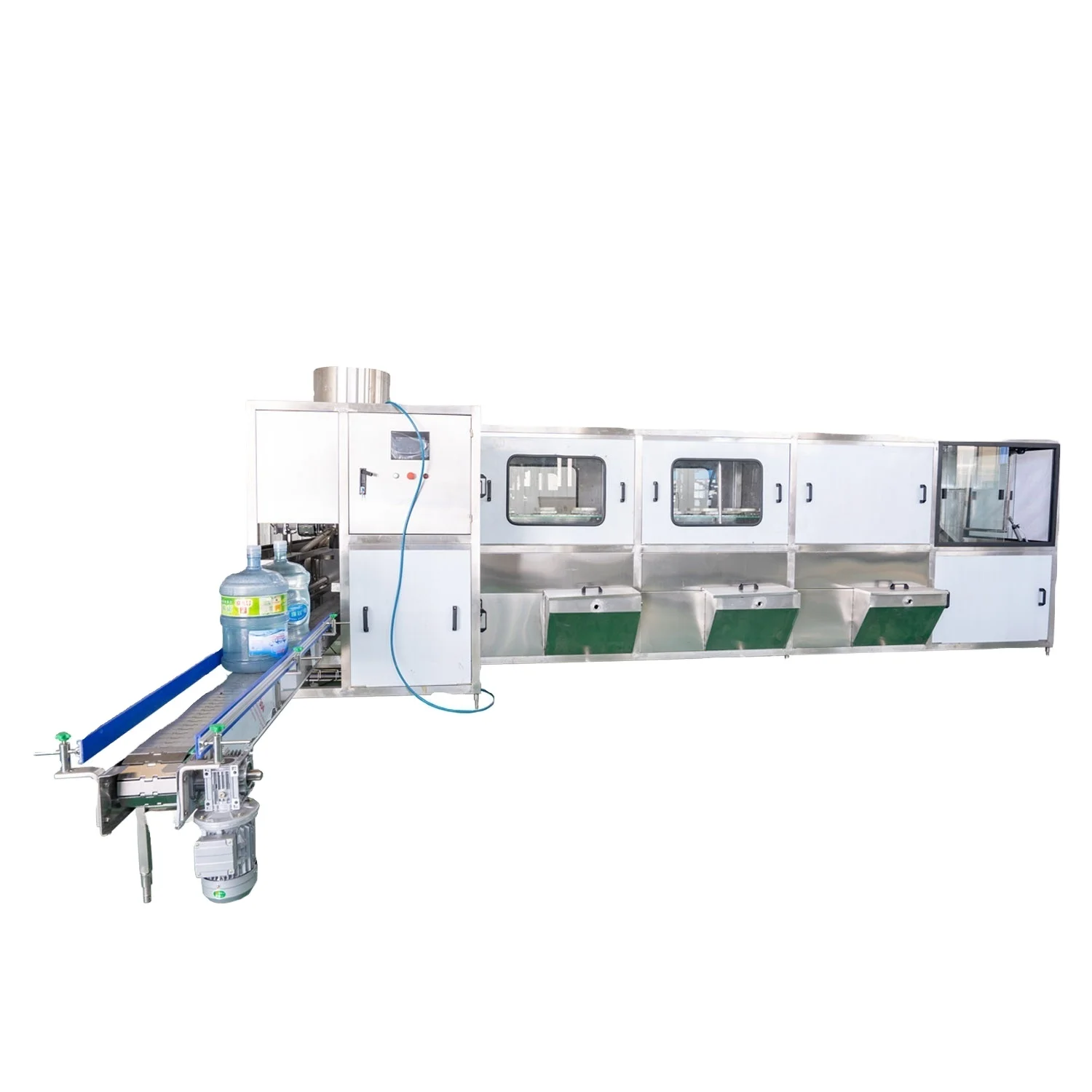

Automatic 500ml Bottle Bottled Water packing and Filling Machine

It is suitable for high temperature resistant PET/Glass/Aluminum bottled drinking water filling. It applies advanced micro-pressure gravity type filling principle, with perfect recirculation system, also can reach separately gas return, without contacting with material, and avoid secondary pollution and oxygen. It is made of high quality SUS304 stainless steel.

Main components of water packaging machine are processed precisely by CNC machine tool.

Special design for washing part

Special design for capping part

Main Features.

Model |

CGF8-8-4 |

CGF14-12-5 |

CGF18-18-6 |

CGF24-24-8 |

|||

Production Capacity

|

2500BPH~3000BPH |

3500BPH~4000BPH |

6500BPH~8000BPH |

10000BPH~12000BPH |

|||

Bottle height |

330mm |

||||||

Bottle diameter |

50~100mm |

||||||

Bottle volume |

0.2~2L |

||||||

Rinsing pressure |

0.2~0.3Mpa

|

||||||

Rinsing water consumption

|

0.5T/H |

0.15-0.35 |

0.15-0.35 |

0.15-0.35 |

|||

Filling precision |

±2~3% |

0.2-0.25 |

0.2-0.25 |

0.2-0.25 |

|||

Power |

3ph,380V/50Hz,1.5Kw |

3ph,380V/50Hz,1.5Kw |

3ph,380V/50Hz,2Kw |

3ph,380V/50Hz,3Kw |

|||

Q: Are you a manufacturer or a trading company?

A: We are the source factory with 25 years of manufacturing experience in beverage machinery. Located in Jinfeng Town, Zhangjiagang City, Jiangsu Province, and China. The transportation is convenient, very close to Pudong Airport and Sunan Shuofang Airport. If your itinerary includes a factory visit, we will pick you up.

Q: How long is your delivery cycle after you order the machinery?

A: Generally it is 40 working days.

Q: Do you have a relevant after-sales system?

A: We have a Perfect after-sales system.

1: 12 months warranty.

2: Many-to-one service, we will solve basic problems through phone, email, WhatsApp, WeChat and video calls. The operation manual will be sent with the machine or via e-mail.

3: If conditions permit, the engineer will go to the buyer's factory to install and test the machine, and train the buyer's staff on how to operate and maintain the machine.

Q: If I want to buy a machine, what information do I need to tell you?

1: What liquid do you want to fill?

2: What is the capacity and height of the bottle?

3: What is the output in one hour?

4: Related water quality analysis reports, etc.

5: Required mechanical voltage

Q: How to ensure that you deliver goods on time and ensure the safety of my funds?

1: We guarantee the on-time delivery and quality of the equipment you purchase through the credit insurance service of the Alibaba platform.

2: With the letter of credit, you can easily lock in the delivery time.

3: After visiting the factory/video watching the factory, you can ensure the authenticity of our bank account.

Q:How do you ensure the quality of the machine?

1: To ensure the accuracy of parts. We are equipped with a variety of professional processing equipment, plus professional processing methods accumulated over the years.

2: Before the machine is assembled, each part is inspected by the inspector.

3: Assemble machines, all with masters with more than 5 years of work experience to operate.

4: After all the equipment is completed, we will connect all the machines and allow at least 12 hours for a complete production line. To test its stability

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ