- Overview

- Inquiry

- Related Products

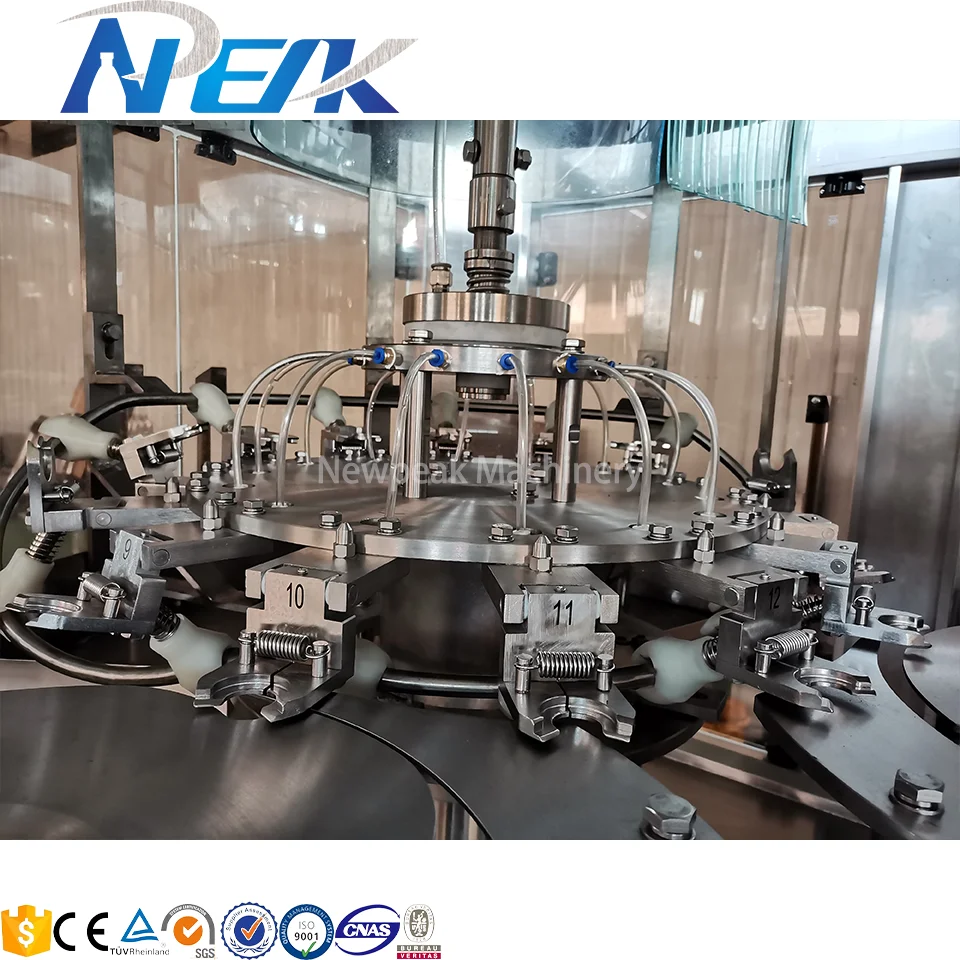

Brand: Newpeak Machinery

If you're in the business of producing beverages, the Aluminium Can Filling Machine is an essential addition to your production line. This piece of equipment is designed to fill cans with your chosen drink product accurately, quickly, and with minimal wastage.

The device is made of top-quality Aluminium, which makes it both durable and lightweight. This implies it could effortlessly be relocated around your manufacturing room as required and it is resistant to corrosion, ensuring a lifespan that is very long. The equipment's sleek design features a control that is built-in that enables one to adjust settings such as for example filling capability and rate, ensuring your products or services are filled to your precise specs.

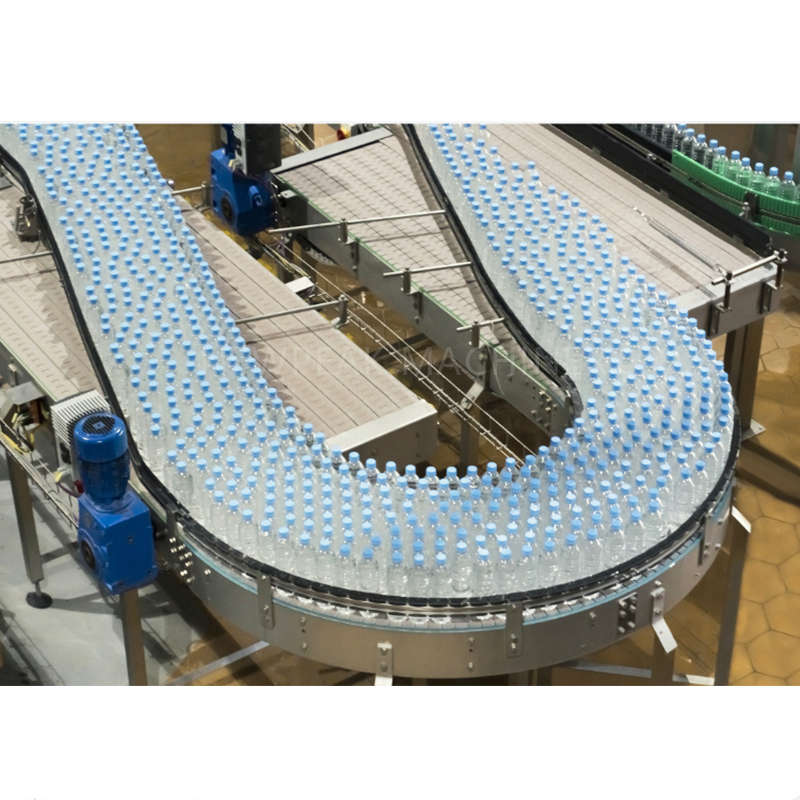

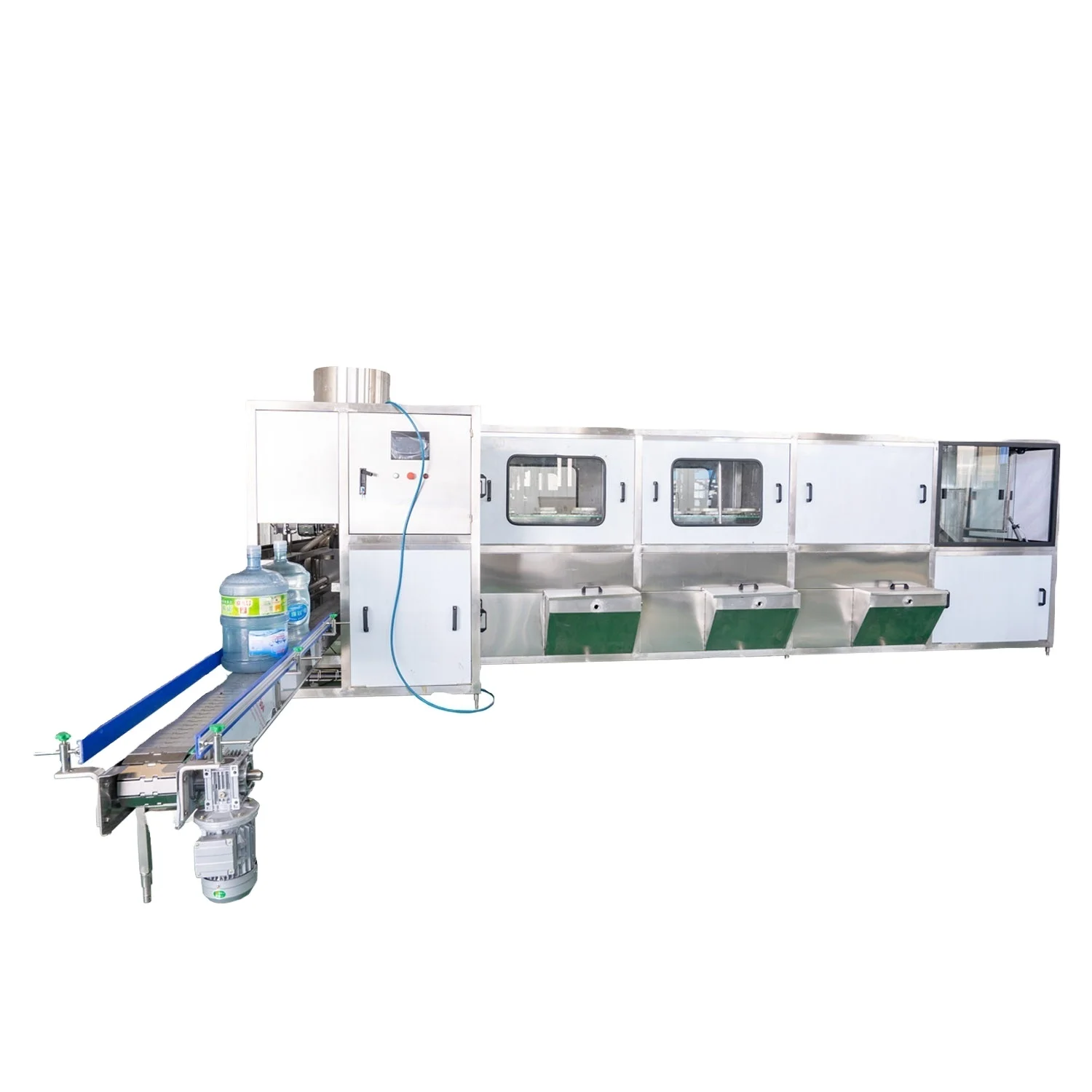

The method that is filling having an empty might that is put regarding the device's conveyor gear. The gear then moves the might towards the section that is filling it really is clamped in position. The device's filling nozzle, that will be created from food-grade steel that is stainless then dispenses your product into the might. The nozzle was created to avoid spillage and minimize foaming, ultimately causing more effective and exact stuffing.

The Aluminium Can Filling Machine appropriate usage having a wide array of beverage items such as sodas, alcohol, and juices. The device can also be suitable for cans of various sizes, from tiny 250ml cans to bigger 500ml cans, which makes it an addition that is versatile your production line.

One of many great things about this system may be the expense that is prospective it could offer organizations. By automating the procedure that is filling you'll reduce work expenses and prevent item wastage due to individual mistake. This could easily result in a better and manufacturing line that is lucrative.

In summary, the Aluminium Can Filling Machine is a reliable and efficient addition to any beverage production line. Its durable construction, adjustable settings, and compatibility with different can sizes and product types make it a versatile and valuable investment for your business. With this machine, you can increase efficiency, reduce wastage, and produce high-quality drink products with ease.

Technical parameter : carbonated beverage production line |

||||||||||||

Model |

DCGF14-12-5 |

DCGF16-16-6 |

DCGF18-18-6 |

DCGF24-24-8 |

DCGF32-32-10 |

DCGF40-40-12 |

||||||

Capacity(for 500ml) |

2000-3000 |

3000-4000 |

4000-5000 |

8000-9000 |

11000-12000 |

13000-15000 |

||||||

Suitable bottle shapes |

circular or square |

|||||||||||

Bottle diameter(mm) |

Dia50-Dia115mm |

|||||||||||

Bottle height (mm) |

160-320mm |

|||||||||||

Compressor air |

0.3-0.7Mpa |

|||||||||||

Washing meidium |

Aseptic water |

|||||||||||

Rinsing pressure |

>0.06Mpa<0.2mpa<>

|

|||||||||||

Application |

carbonated beverage production line |

|||||||||||

Total power (KW) |

4.4kw |

4.8kw |

5.2kw |

6.2kw |

7.5kw |

8.2kw |

||||||

Overall dimensions |

2.5*1.9m |

2.7*1.9m |

2.8*2.15m |

3.1*2.5m |

3.8*2.8m |

4.5*3.3m |

||||||

Height |

2.3m |

2.5m |

2.5m |

2.5m |

2.5m |

2.6m |

||||||

Weight(kg) |

3000kg |

4000kg |

4500kg |

6000kg |

8500kg |

10000kg |

||||||

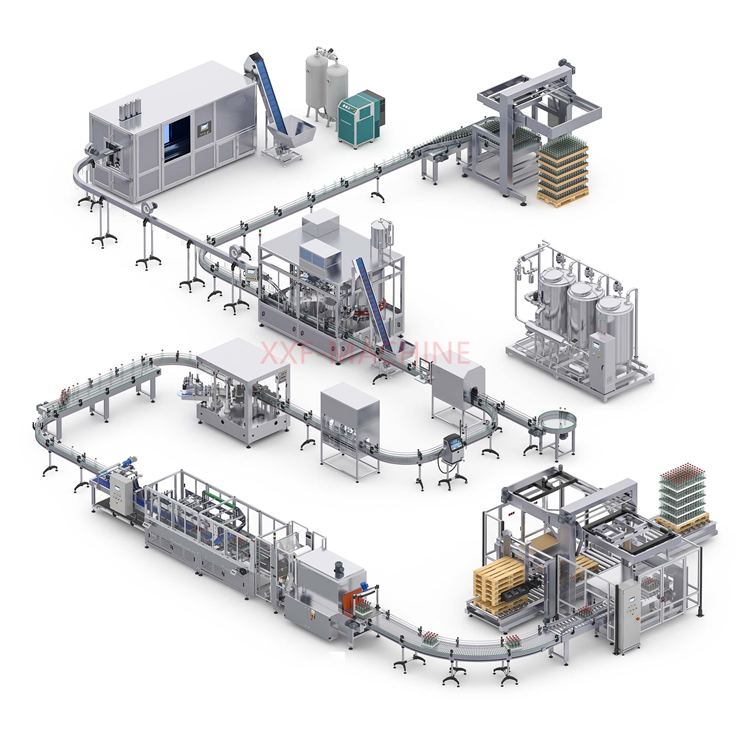

water treatment

Beverage Mixing System

---Friendly HMI with easy switch for multi-languages. ---The filling valve is designed with the tidy and safe valve body, the material quality can be fully guaranteed. ---Advanced electronic isobaric filling valves to be used for a variety of materials, higher filling temperatures, higher filling accuracy, and lower carbon dioxide consumption can be achieved. ---The unique patented technology for bottle rinsing, no bottle without flushing at fixed stations, saving water for customers ---Similar capping technology from Krones, Germany, each torque balance, high efficiency

Labeling Machine

Bottle Packing System

Bottle Blowing System

machine,including air compressor system and water cooling system .

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ