- Overview

- Inquiry

- Related Products

Newpeak Machinery

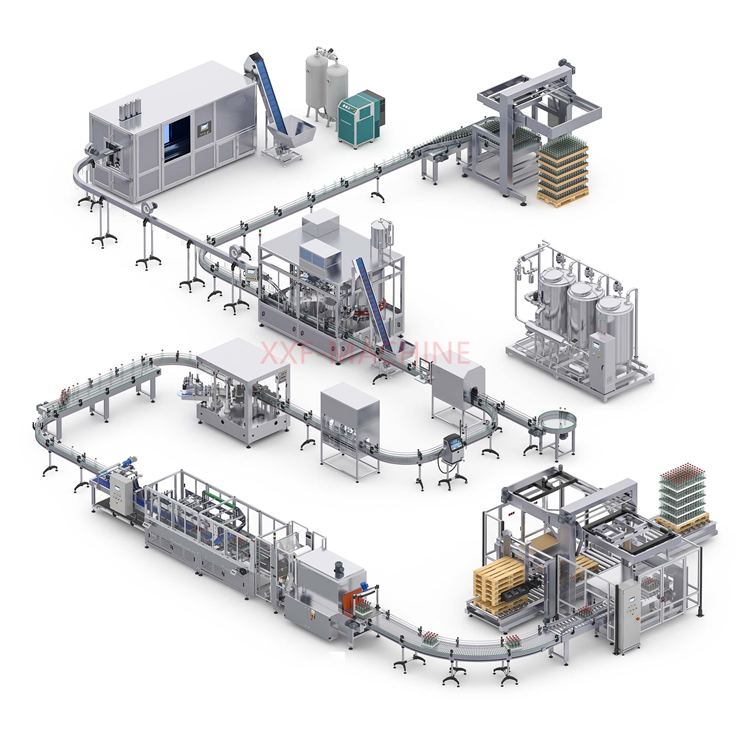

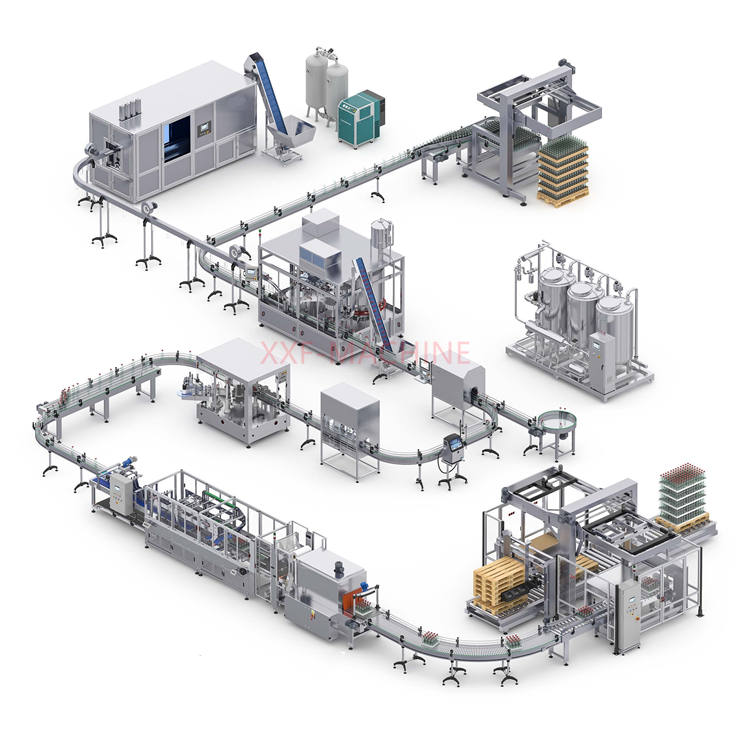

Introducing the little Bottle Vial Water Filling Line - the answer is clear perfect stuffing and capping little bottles and vials with water quickly and effectively.

Fashioned with convenience in your mind, this stuffing line just isn't difficult and compact to your workplace. Maybe it really is seamlessly included to your manufacturing is line certainly present as a standalone unit. The tiny Bottle Vial Water Filling Line would work with the choice of small containers and vials, including some people that have a convenience of 10ml to 500ml.

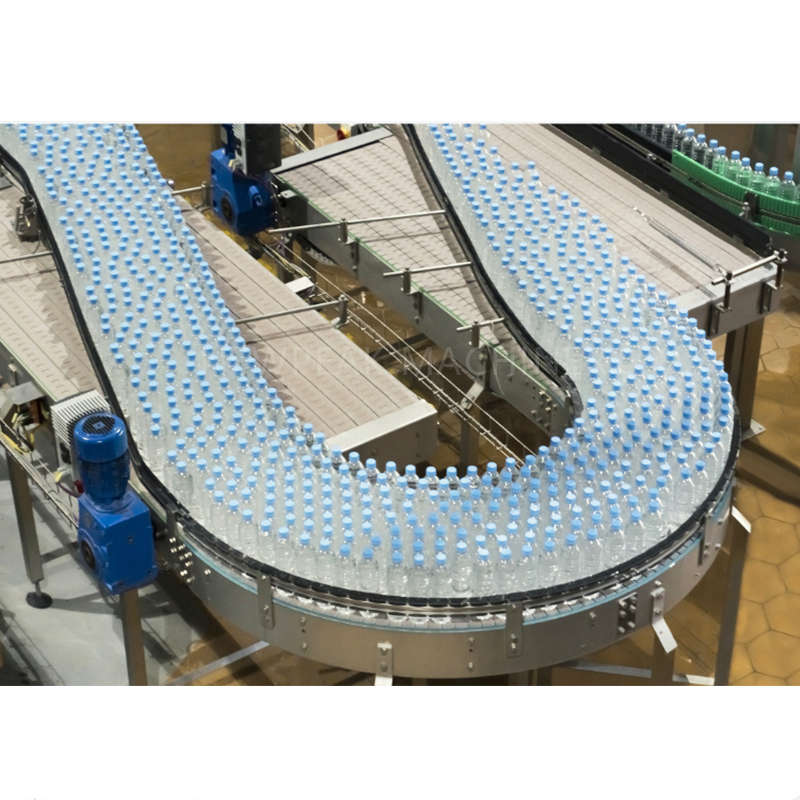

This product guarantees constant and accurate filling for every container and vial having its functions which can be advanced. The stuffing procedure is easy- and quick simply load the containers into the conveyor and allow the device care for the remainder. The stuffing line can manage as much as 200 containers every single moment that is full boosting your production ability and boosting your important things.

The little Bottle Vial liquid Filling Line additionally has automated capping and system is labeling eliminating the requirement for handbook make use of those procedures along with its quick and stuffing procedure is accurate. This implies you will put away your valuable self-time, reduce work expenses, making certain a manufacturing and procedure is smooth efficient.

The machine is manufactured far from top-quality materials that ensure durability and security, that makes it an investment is good sensible any ongoing company wanting to improve their production procedures. The line is filling a task is easy keep and requirements cleaning this certainly minimal servicing, reducing upkeep expenses and downtime.

The little Bottle Vial Water Filling Line is produced with safety in mind. It features an array of security features including an emergency end protection and switch sensors in order to prevent accidents. It will help to make certain your workers are safe while running the apparatus, offering you reassurance.

Purchase this method to improve your production ability, reduce labor costs, and ensure a smooth and production procedure is efficient today.

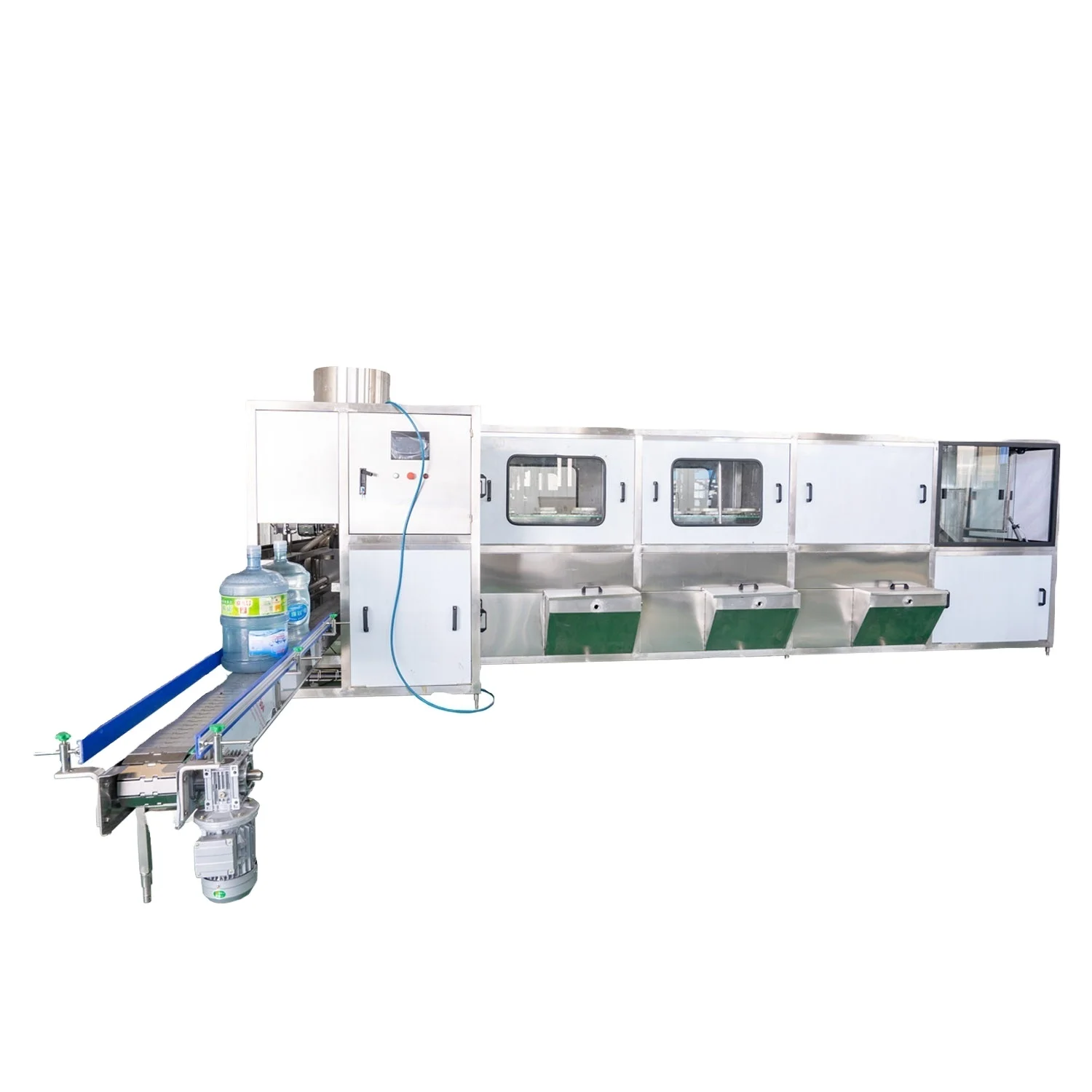

Peak Water Bottling Machine Equipment Plant Supply Complete Automatic Water Bottling Machine Mineral

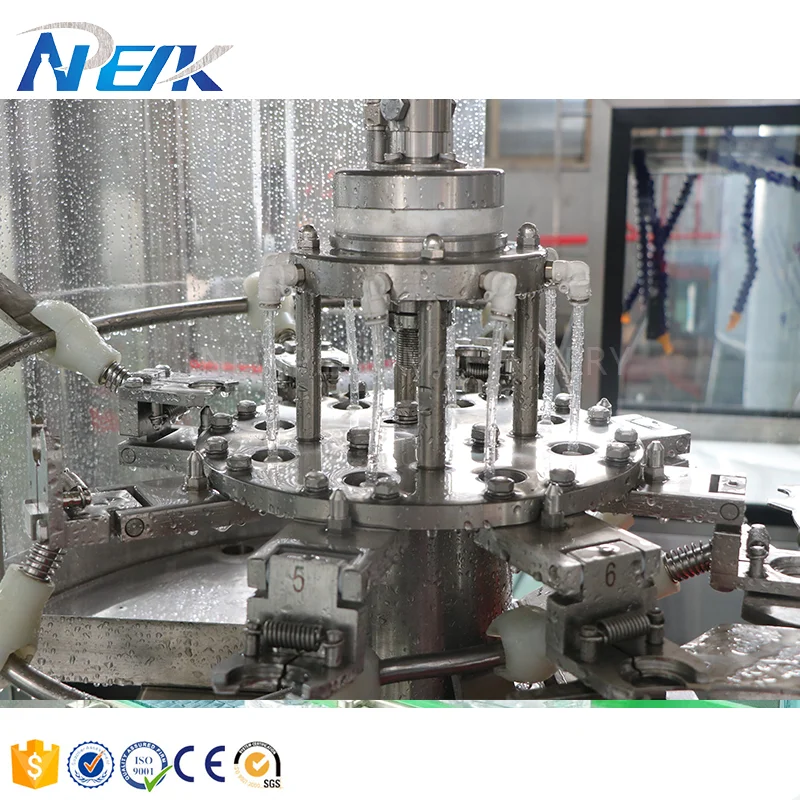

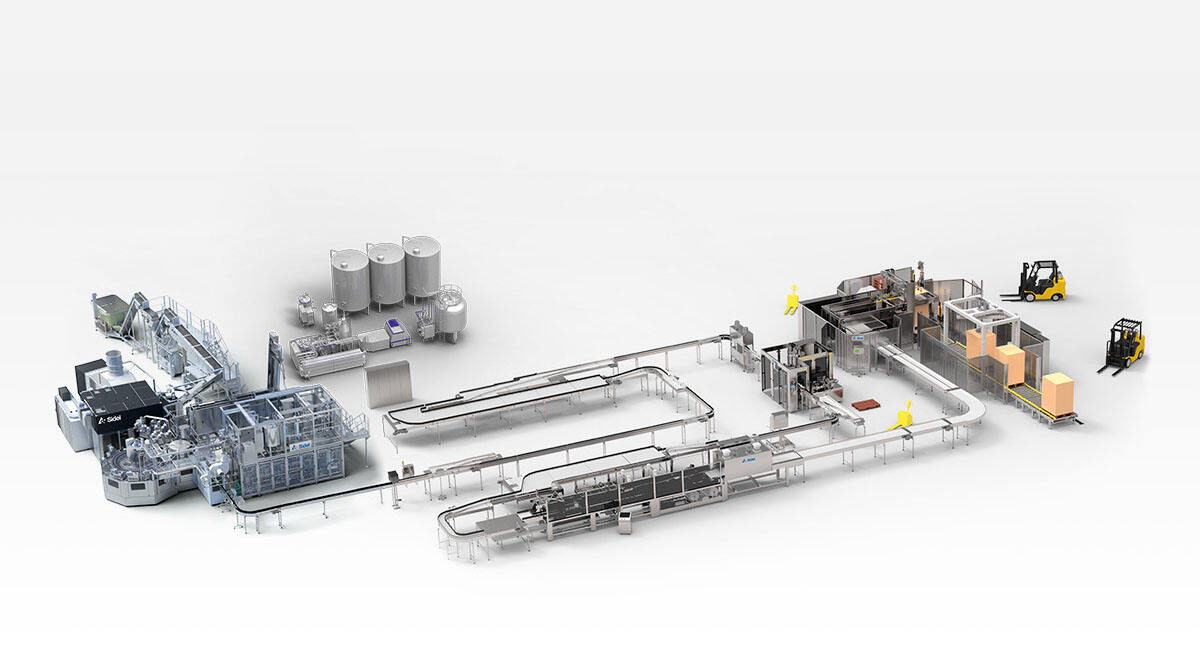

This pet bottle drinking water pulp filling machinery has washer, filler, and capper three functions in one body, total process is automatic.

Automatic 500ml Bottle Bottled Water packing and Filling Machine

It is suitable for high temperature resistant PET/Glass/Aluminum bottled drinking water filling. It applies advanced micro-pressure gravity type filling principle, with perfect recirculation system, also can reach separately gas return, without contacting with material, and avoid secondary pollution and oxygen. It is made of high quality SUS304 stainless steel.

Main components of water packaging machine are processed precisely by CNC machine tool.

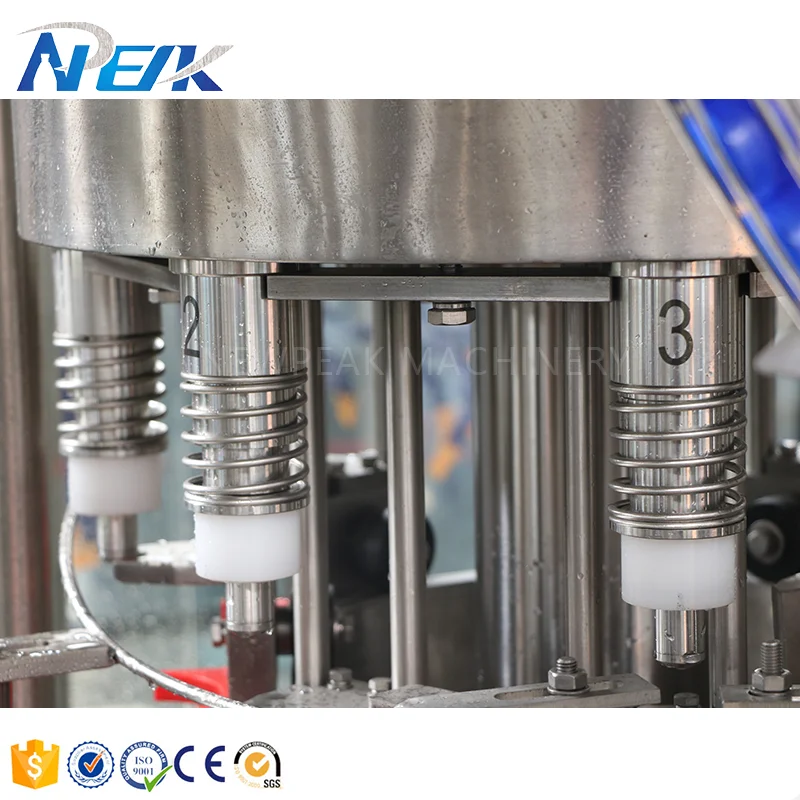

Special design for washing part

Special design for capping part

Main Features.

Model |

CGF8-8-4 |

CGF14-12-5 |

CGF18-18-6 |

CGF24-24-8 |

|||

Production Capacity

|

2500BPH~3000BPH |

3500BPH~4000BPH |

6500BPH~8000BPH |

10000BPH~12000BPH |

|||

Bottle height |

330mm |

||||||

Bottle diameter |

50~100mm |

||||||

Bottle volume |

0.2~2L |

||||||

Rinsing pressure |

0.2~0.3Mpa

|

||||||

Rinsing water consumption

|

0.5T/H |

0.15-0.35 |

0.15-0.35 |

0.15-0.35 |

|||

Filling precision |

±2~3% |

0.2-0.25 |

0.2-0.25 |

0.2-0.25 |

|||

Power |

3ph,380V/50Hz,1.5Kw |

3ph,380V/50Hz,1.5Kw |

3ph,380V/50Hz,2Kw |

3ph,380V/50Hz,3Kw |

|||

Q: Are you a manufacturer or a trading company?

A: We are the source factory with 25 years of manufacturing experience in beverage machinery. Located in Jinfeng Town, Zhangjiagang City, Jiangsu Province, and China. The transportation is convenient, very close to Pudong Airport and Sunan Shuofang Airport. If your itinerary includes a factory visit, we will pick you up.

Q: How long is your delivery cycle after you order the machinery?

A: Generally it is 40 working days.

Q: Do you have a relevant after-sales system?

A: We have a Perfect after-sales system.

1: 12 months warranty.

2: Many-to-one service, we will solve basic problems through phone, email, WhatsApp, WeChat and video calls. The operation manual will be sent with the machine or via e-mail.

3: If conditions permit, the engineer will go to the buyer's factory to install and test the machine, and train the buyer's staff on how to operate and maintain the machine.

Q: If I want to buy a machine, what information do I need to tell you?

1: What liquid do you want to fill?

2: What is the capacity and height of the bottle?

3: What is the output in one hour?

4: Related water quality analysis reports, etc.

5: Required mechanical voltage

Q: How to ensure that you deliver goods on time and ensure the safety of my funds?

1: We guarantee the on-time delivery and quality of the equipment you purchase through the credit insurance service of the Alibaba platform.

2: With the letter of credit, you can easily lock in the delivery time.

3: After visiting the factory/video watching the factory, you can ensure the authenticity of our bank account.

Q:How do you ensure the quality of the machine?

1: To ensure the accuracy of parts. We are equipped with a variety of professional processing equipment, plus professional processing methods accumulated over the years.

2: Before the machine is assembled, each part is inspected by the inspector.

3: Assemble machines, all with masters with more than 5 years of work experience to operate.

4: After all the equipment is completed, we will connect all the machines and allow at least 12 hours for a complete production line. To test its stability

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ