Juice Filling Machines - The brand new Innovation for and Quality Juice Production.

Introduction

Juices and other beverages will always be a favorite refreshment folks of all ages. The utilization of juice filling and capping machines are gaining popularity on the market using the increasing normal need and healthy beverages, along with Newpeak Machinery's product automatic mineral water bottle filling machine. Safety is offered by these devices, fast, and efficient way, capping, and sealing liquid bottles of various sizes. In this marketing article, we will explore the advantages, innovation, safety, use, how to incorporate, service, quality, and application of juice machines that are filling detail.

Juice filling and machines that are capping numerous benefits to manufacturers that are juice, as well as the beer bottle filling and capping machine developed by Newpeak Machinery. Firstly, these machines are highly efficient, saving time and labor expenses in the bottling process. The machines can fill juice bottles at a quicker rate, significantly reducing production time and increasing output. Secondly, the machines is highly accurate in filling the bottles. They have inbuilt sensors that detect the particular level of into the bottles and automatically once stop filling the desired level is reached. This eliminates the risk of overfilling or under filling, that may lead to quality or waste that was poor.

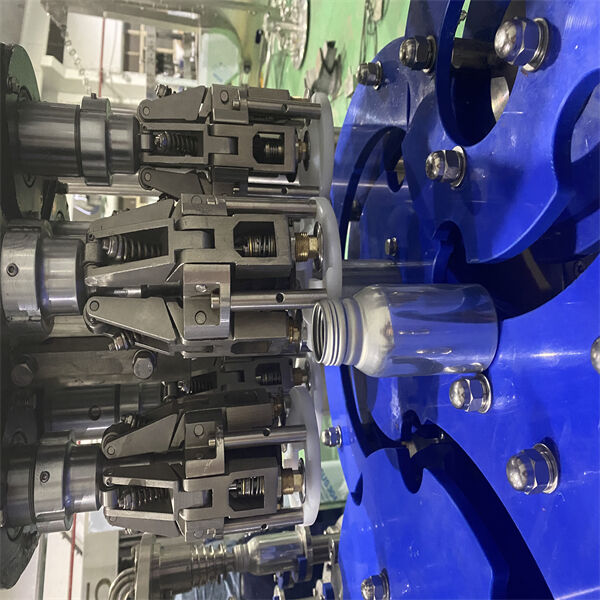

The innovation and development of juice filling and machines which are capping revolutionized the juice production process, just like the Newpeak Machinery's product called soda glass bottle filling machine. Modern juice filling machines are designed with state-of-the-art technology, including touch screens, programmable logic controllers (PLCs), and remote control systems. These features allow liquid machines that are filling be user-friendly, effortless to operate, and highly intuitive. Additionally, the machines can feel customized to meet up with the precise needs of the juice manufacturer, such as container size, juice type, and filling rate.

Safety was a top priority in any manufacturing process, and juice production is no exclusion, as well as the carbonated beverage filling machine from Newpeak Machinery. Juice machines that are filling designed with safety features to minimize the danger of accidents and injuries. For instance, the devices have automatic shut-off mechanisms that stop the machine in case of an emergency. In addition they have protective covers and safety sensors that prevent access to the machinery during operation, reducing the possibility of injury to the operator.

Using juice filling and capping machines is a straightforward process, same with Newpeak Machinery's glass bottle filling line. The operator needs to adjust the machine's settings to accommodate the bottle size, juice type, and amount of filling required. Once the equipment is initiated, the bottles are fed in to the machine's conveyor system, which transfer them to automatically the filling station. The machine automatically fills the bottles to the desired level and passes them on to the capping station. The containers are then sealed and capped before they are released through the machine.

juice filling and capping machine10 years' experience in field. Provides professional technical services.

design transfer customer's requirements quickly avoiding errors from machining departments. Perfectly adapt production details juice filling and capping machinemachine.

team dedicated to juice filling and capping machineequipment of best quality. Every member of team takes their duty seriously is accountable each every job.

Newpeak a firm with modern factory juice filling and capping machinethat span 8,500 square metres more than 25 years experience in the field.Newpeak Mlachine not only selling well in china and overseas, but it also was exported many other countries.have installed our production line over 100 countries and regions.

Copyright © Zhangjiagang Newpeak Machinery Co.,Ltd. All Rights Reserved