Introduction

Are you looking for Industrial bottle filling machine that fills containers with different fluids with the use of Newpeak Machinery water filling machines and services and products? Either for small or big interprises. Look no further as these devices are employed in industries like food and beverage, pharmaceutical, chemical, as well as others being number one. So let's dive right into it as we discussed the information further.

The Industrial bottle filling machine has many advantages. Firstly, it is efficient and will fill bottles with fluids quickly. Secondly, it reduces error peoples it's automatic. Thirdly, it's very economical as it can certainly accurately fill bottles, which decreases waste. Finally, it's versatile like the Newpeak Machinery and will fill several types of bottles with different types of fluids.

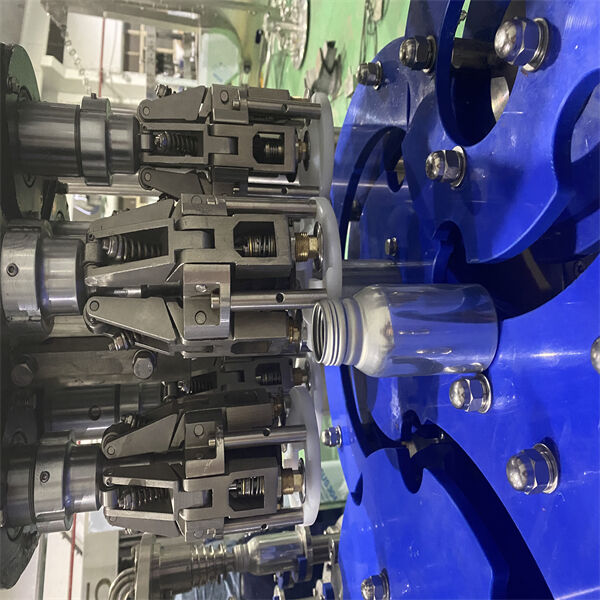

Industrial bottle filling machine have come an easy method long terms of innovation with the use of Newpeak Machinery liquid filling. They are in possession of features like automated bottle feeding, automatic cap positioning, and labeling automatic. These features are making the devices more efficient and also have reduced work manual. Additionally, some machines have sensors that detect any spills or overflows, which enhances security.

Security is an aspect important of Industrial bottle filling machine. These devices like the Newpeak Machinery have many features that ensure security. Firstly, they have security guards that protect the operator and prevent any accidents. Secondly, some machines have safety sensors that stop the machine in case there is any malfunction. Some machines have safety interlocks that prevent the device from beginning until all safety guards are in spot.

The Industrial bottle filling machine is very simple to use. Firstly, the operator needs to adjust the machine to match the product and container specs. Secondly, the bottles are placed regarding the conveyor gear, and they're filled by the machine as well as the Newpeak Machinery small scale bottle filling machine. Lastly, the operator can monitor the filling process while making any adjustments which can be necessary.

design transfer customer's requirements quickly avoiding errors from all industrial bottle filling machinedepartments.Perfectly adapt production details filling machine.

team dedicated to industrial bottle filling machineequipment of best quality. Every member of team takes their duty seriously is accountable each every job.

More than 10 technical engineers as troubleshooting engineers.Each engineer more than 10 years work experience.Provide highest industrial bottle filling machinetechnical support.

Newpeak is business with a an industrial workshop that modern and spacious, measuring an area of 8,000 square meters. also has over 25 years of expertise in the industry.Newpeak industrial bottle filling machineis not only selling well in china, but also exported many other countries.production line has been use over 100 countries and regions.

The operator has to follow a few actions to make use of a Industrial bottle filling machine. Firstly, the operator needs to start the equipment and adjust it to fit this product and container specs. Next, the bottles are positioned in the conveyor gear, plus they are filled by the device and the Newpeak Machinery. Lastly, the operator can monitor the filling procedure making any changes which can be necessary.

Many Industrial bottle filling machine include after-sales service and upkeep packages. These packages are made to make sure that the devices perform optimally of Newpeak Machinery bottle filling line as they are maintained frequently. Also, the ongoing service professionals are trained to determine any dilemmas and repair them quickly.

Quality is a aspect critical of Industrial bottle filling machine. These devices are developed by Newpeak Machinery to last and perform optimally for many years. Also, they've been manufactured from top-notch materials that can withstand the rigors of commercial surroundings. Finally, they undergo stringent quality checks to ensure they meet industry standards.

Copyright © Zhangjiagang Newpeak Machinery Co.,Ltd. All Rights Reserved