Filling and Capping Machines: Advantages and Innovations

Are you currently searching for a filling and capping device? In that case, you've come to the right place. Newpeak Machinery filling and capping machine are a definite key component in the manufacturing procedure, allowing businesses to quickly package their products or services. We will explore the benefits and innovations among these devices, as well as how to use them and the quality of its service.

One benefit significant of Filling and Capping Machines is the efficiency. These Newpeak Machinery water bottle filling and capping machine help to streamline the packaging process for companies, making it possible for more output with less labor individual. This increased efficiency can lead to reduced charges for both the maker and the customer.

In addition to efficiency, Filling and Capping Machines also provide a level high of efficiency. With the ability to determine, fill electronically, and cap services and products, there is a much smaller potential for errors. This accuracy can also lead to less item waste, saving organizations cash in the long run.

As technology continues to advance, so do Filling and Capping Machines. Innovations in these devices have permitted for even more efficiency and precision, in addition to improved safety measures.

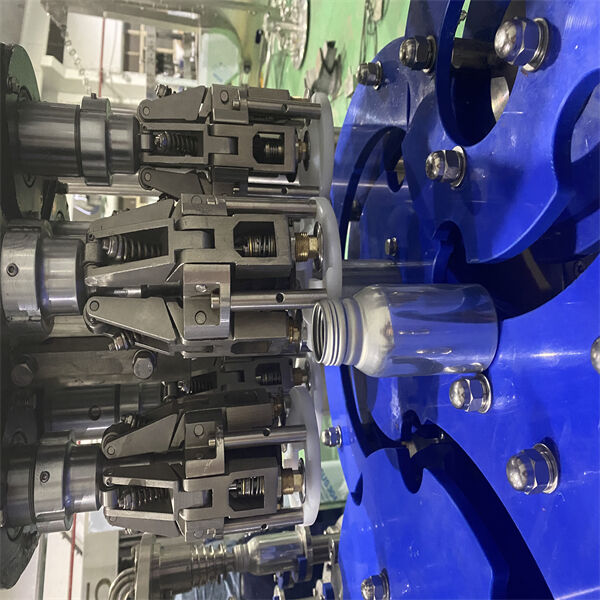

One innovative function some filling and capping machines is the utilization of servo motors. These motors offer precise control of the filling and capping process resulting in a high level of precision. Another innovation of Newpeak Machinery filling capping machine is the incorporation of touchscreen interfaces, making the devices more straightforward to use and reducing the possibility of operator mistake.

Safety is always a top concern to manufacturing; filling and capping machines are no exclusion. Numerous devices now include safety interlocks, which prevent the machine from operating if certain security precautions aren't in position. These interlocks can sometimes include guards across the filling and capping areas where sensors that detect when an employee is within the danger zone.

Furthermore, some filling and capping machines are built to utilize dangerous materials. These Newpeak Machinery water filling machines is made with specific materials, such as stainless steel, to resist the effects of corrosive or dangerous substances.

Using Filling and Capping Machines appear daunting in the beginning, but it is fairly simple. The initial step is to set the machine up with all the appropriate filling and capping elements. This could consist of adjusting the height of the filling nozzles and changing out the caps.

When the device is established, it can be switched on and programmed with all the desired settings, for instance the level of product become filled or the torque for capping the containers. After these settings are entered, the Newpeak Machinery water bottling machines can be started, also it will automatically fill and cap the products.

team dedicated to filling and capping machineequipment of best quality. Every member of team takes their duty seriously is accountable each every job.

Newpeak a business with a modern factory facilities span 8,500 square metres more than 25 years expertise in the industry.filling and capping machineMlachine is not just popular China, but it's also being exported many other countries.production line has been used in over 100 countries regions.

design transfer customer's requirements quickly avoiding errors from machining departments. Perfectly adapt production details filling and capping machinemachine.

Each engineer 10 years filling and capping machine in industry. Professional technical support.

Copyright © Zhangjiagang Newpeak Machinery Co.,Ltd. All Rights Reserved