- Pregled

- Upit

- Povezani proizvodi

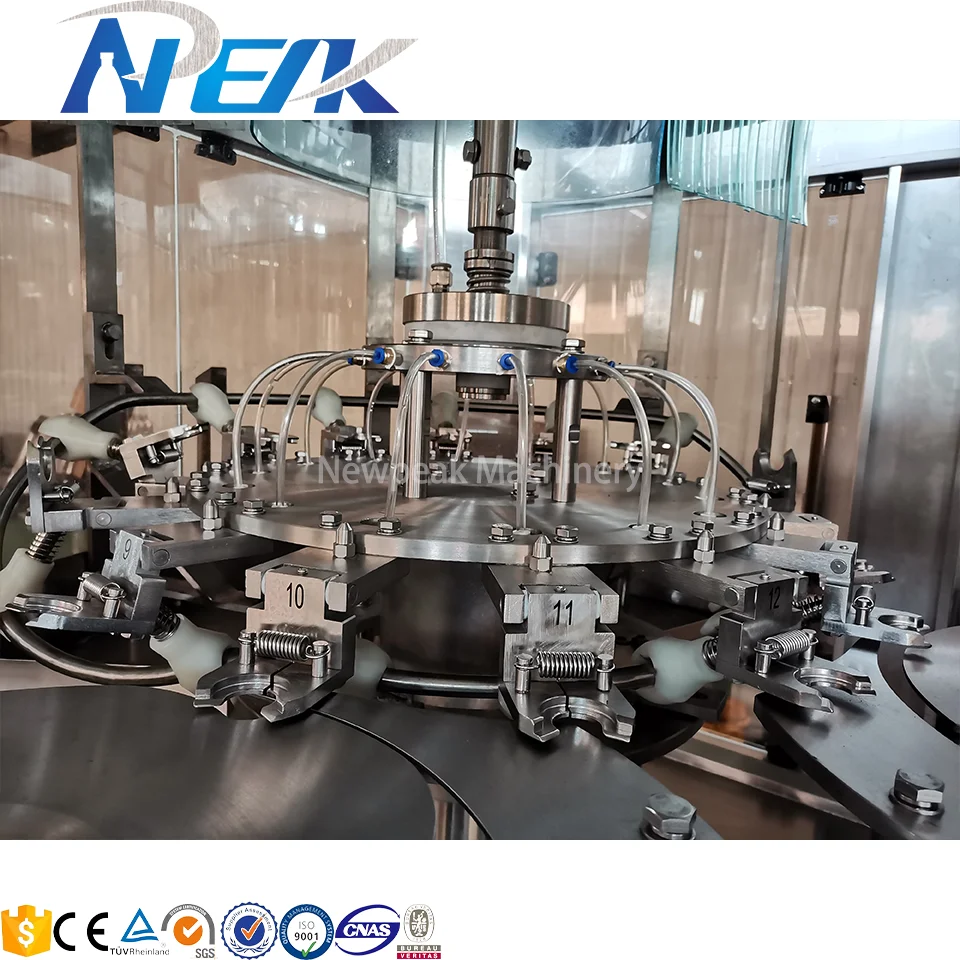

Brend: Newpeak Machinery

Ako ste u poslu proizvodnje pića, stroj za punjenje aluminijumske kase je neophodan dodatak vašoj liniji proizvodnje. Ovaj uređaj je dizajniran da precizno, brzo i sa minimalnom gubitičkom puni kase odabranim pićem.

Uređaj je izrađen od najkvalitetnijeg aluminijuma, što ga čini i trajanom i laganim. To znači da ga možete lako premestiti po vašoj proizvođačkoj sobi po potrebi, a otporan je na koroziju, osiguravajući vrlo dug životni vek. Stroj ima elegantan dizajn sa ugrađenim kontrolerom koji omogućava prilagođavanje postavki poput mogućnosti punjenja i brzine, osiguravajući da su vaši proizvodi napuni prema tačnim specifikacijama.

Metod koji se ispunjava praznim može da bude postavljen u odnosu na prenosni sistem uređaja. Zubački sistem zatim pomeri može prema sekciji za ispunjavanje, gde je fiksiran na mesto. Ispraznuvalna musorija uređaja, koja je izrađena od hranljive neroste, onda raspoređuje proizvod unutar može. Musorija je dizajnirana da spreči protjecanje i smanji penjanje, što dovodi do efikasnijeg i tačnijeg ispuna.

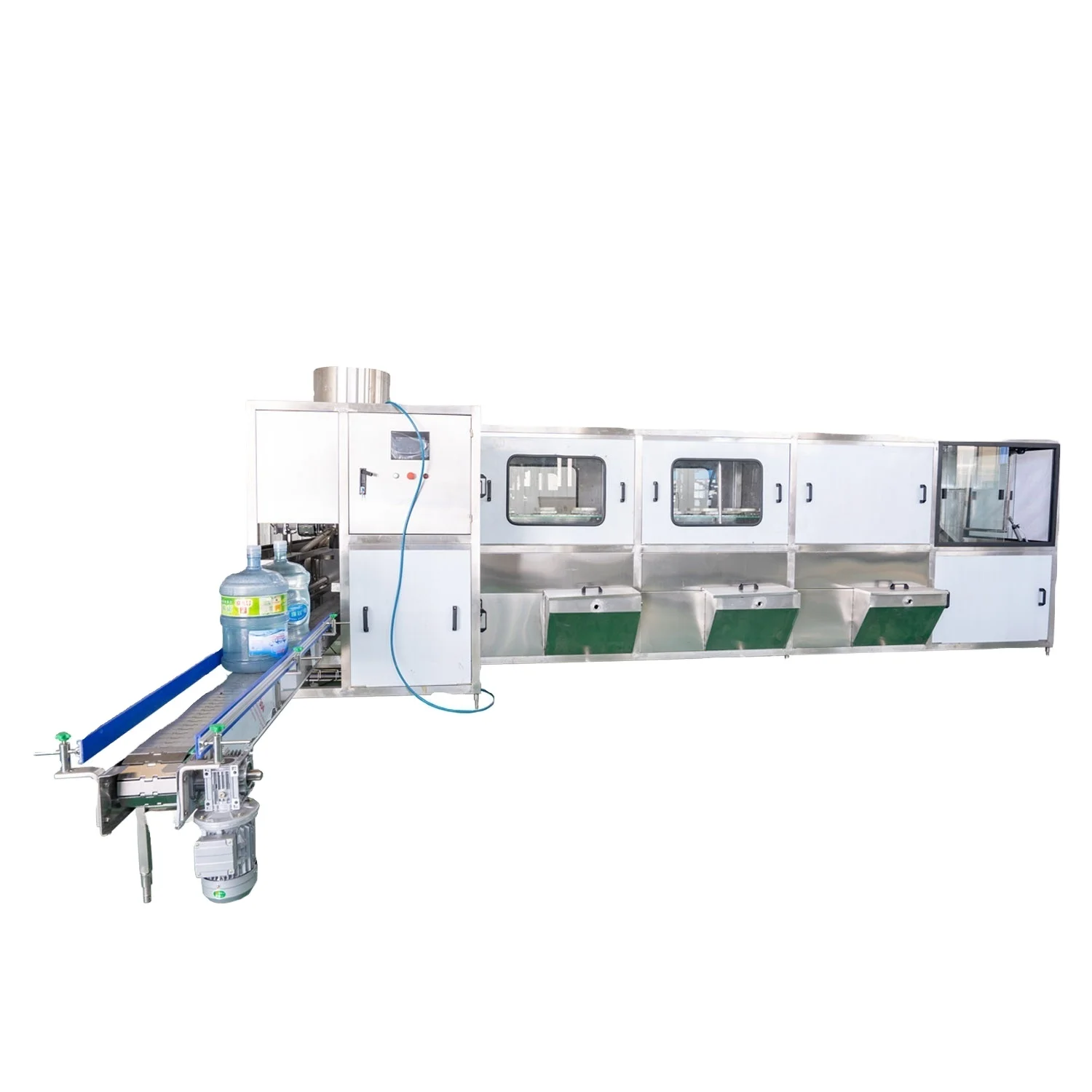

Mašina za ispunjavanje aluminijumske boce prikladna je za širok spektar pića, kao što su limunade, alkohol i sokovi. Uređaj takođe može da radi sa bočicama različitih veličina, od malih 250ml bočica do većih 500ml bočica, čime postaje fleksibilna dodatak vašoj proizvodnoj liniji.

Jedna od mnogih izuzetnih stvari o ovom sistemu je moguća štednja koju može pružiti preduzećima. Automatizovanjem procesa ispunjavanja možete smanjiti troškove rada i sprečiti gubitak proizvoda zbog ljudskih grešaka. To može lako dovesti do bolje i profitabilnije linije proizvodnje.

U krizi, mašina za ispunjavanje aluminijumske kuse je pouzdan i efikasan dodatak bilo kojoj liniji proizvodnje pića. Njena trajna konstrukcija, prilagodljiva podešavanja i saglasnost sa različitim veličinama kusa i vrstama proizvoda čine je fleksibilnom i vrednom investicijom za vaše poslovanje. Sa ovom mašinom, možete povećati efikasnost, smanjiti gubitke i proizvoditi visokokvalitetne pića lako.

Tehnički parametri: linija za proizvodnju ugljenatih pića |

||||||||||||

Model |

ДЦГФ14-12-5 |

DCGF16-16-6 |

ДЦГФ18-18-6 |

ДЦГФ24-24-8 |

ДЦГФ32-32-10 |

ДЦГФ40-40-12 |

||||||

Kapacitet (za 500ml) |

2000-3000 |

3000-4000 |

4000-5000 |

8000-9000 |

11000-12000 |

13000-15000 |

||||||

Odgovarajuće oblike bocica |

krugaš ili kvadratni |

|||||||||||

Prečnik bačke (mm) |

Dia50-Dia115mm |

|||||||||||

Visina boce (mm) |

160-320mm |

|||||||||||

Kompresor vazduh |

0.3-0.7Mpa |

|||||||||||

Perajno sredstvo |

Sterilna voda |

|||||||||||

Притисак прумивања |

>0.06Mpa<0.2mpa<>

|

|||||||||||

Primena |

linija proizvodnje uzbuđujućih pića |

|||||||||||

Ukupna snaga (KW) |

4.4КВ |

4.8KW |

5,2КВ |

6.2kW |

7.5KW |

8.2kw |

||||||

Ukupne dimenzije |

2.5*1.9m |

2.7*1.9m |

2.8*2.15m |

3.1*2.5m |

3.8*2.8m |

4.5*3.3m |

||||||

Visina |

2,3 м |

2.5m |

2.5m |

2.5m |

2.5m |

2.6m |

||||||

Težina (kg) |

3000kg |

4000kg |

4500kg |

6000kg |

8500kg |

10000кг |

||||||

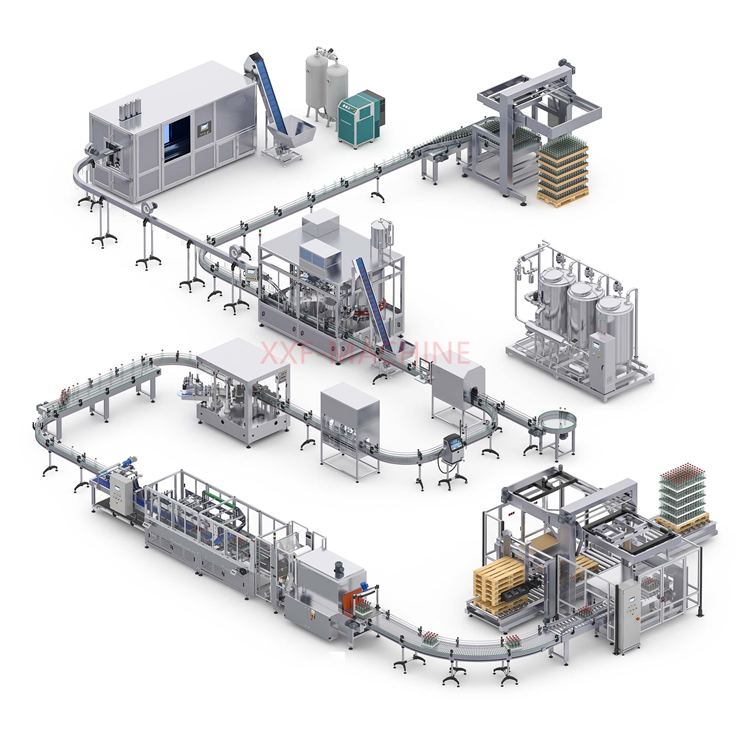

треатмент воде

Sistem za mešanje pića

---Prijateljski korisnički interfejs sa lako prebacivanjem na više jezika. ---Ventil za punjenje je dizajniran sa čistim i sigurnim telom ventila, a kvalitet materijala može biti potpuno osiguran. ---Koristi se napredni elektronski izobarne ventil za punjenje različitim materijalima, što omogućava višu temperaturu punjenja, veću tačnost punjenja i nižu potrošnju ugljične dimovine. ---Jedinstvena patentovana tehnologija za pranje boca, bez boce bez prašenja na fiksiranim stanicama, štedi vodu kupcima. ---Slična tehnologija zatvaranja od Krones, Nemačka, svaki ravnotežni torzijski moment, visoka efikasnost.

Машина за ознаку

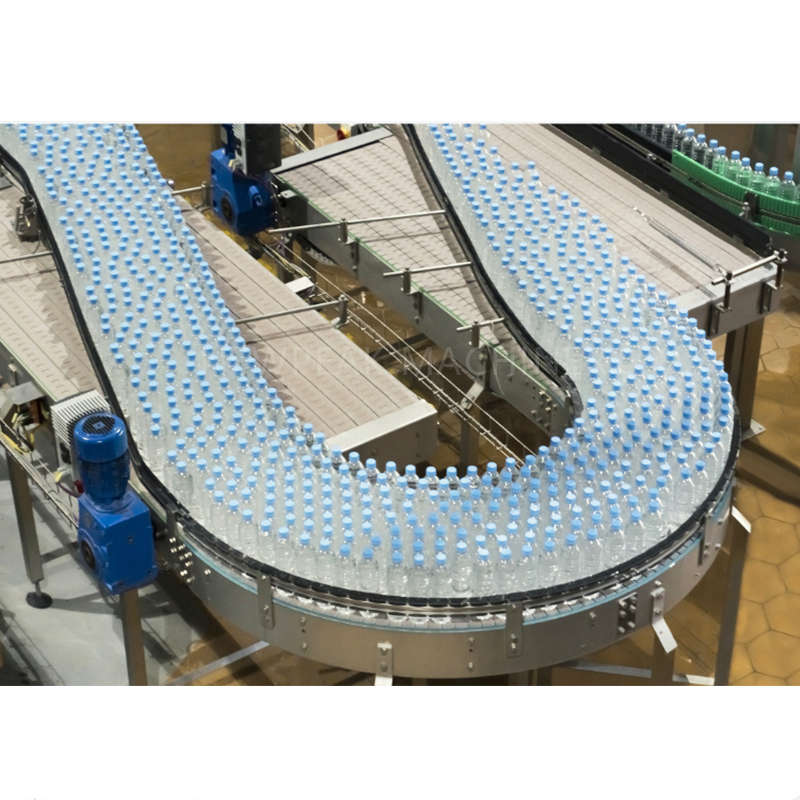

Sistem za ambalazu boca

Sistem za direktno formiranje boca

uključujući i kompresorski sistem i sistem za hlađenje vodom.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ