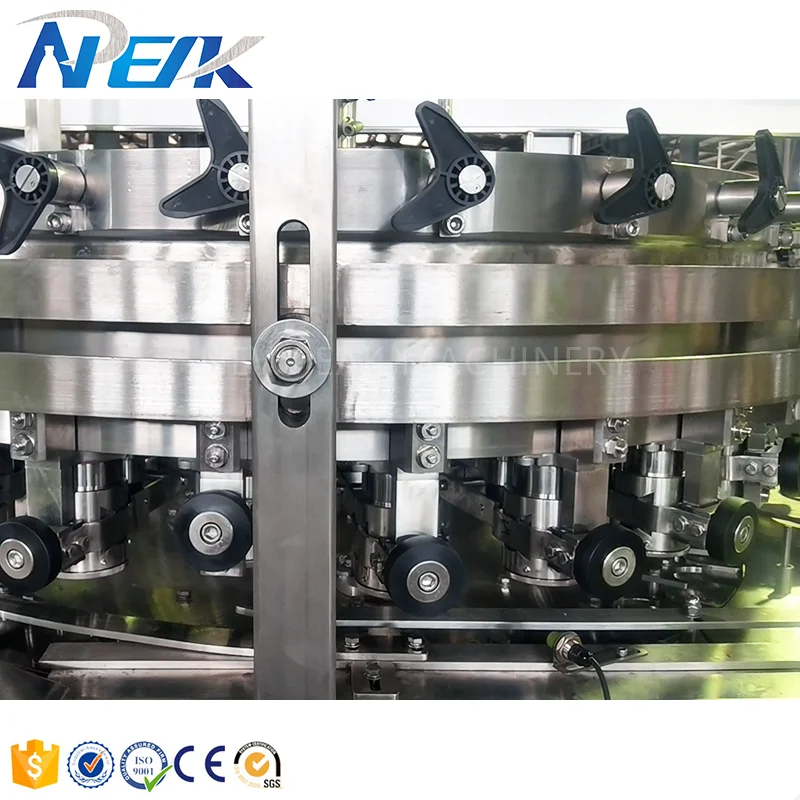

A filler capper is a particular piece of equipment which, as the name suggests, fills bottles with liquid and seals them securely so that they can be shipped further down along the production line. One of the most important machines for accelerating production and guaranteeing faultlessness Used in industries like food & beverage, pharma and cosmetics.

Filling And Capping Machine Benefits

Increased Productivity: The use of a capping and filling machine has an incredible capability to fill as well as cap hundreds of bottles within just 1 hour, thus making the production process that much faster.

Accurate: The machine ensures perfect liquid to bottle ratio every time, significantly cutting down on waste.

Reliability: The filling and capping machine can ensure the consistent performance of bottle filing, as well as sealing so that product uniformity is abided by.

Requires minimal human touch with the product, reducing contamination and improving safety making it a more hygienic production process.

Filling and Capping Machine Innovation

Over the past several years, a number of filling and capping machines have been developed thanks to recent technology advances. For example, the use of electronic sensors has improved filling and capping performance in terms of both quality and speed. They are capable of sensing if the bottles have a proper seal on them, which helps in quality checking.

Filling and Capping Machine Safety

The filling and capping machines used in food, pharmaceuticals or cosmetics carry special risks which can have a critical impact on safety requirements to make sure workers are not harmed by the machine. We make sure to use only the best grade materials available in Food Grade & Pharma Grade Categories. Also, they are designed to come with no product contamination durring the filling and post capping stages.

Using Filling and Capping Machine

Filling and capping operate filling machine is a simple matter. First the machine is programmed to measure out liquid into each bottle. Then, the bottles are conveyed towards a filling and capping station. This is the area for bottled filling, where liquid pours on bottles until it reaches lids being attached tightly. After capping, the bottles are then moved to another conveyor belt for labeling and packaging.

Quality of Filling and Capping Machine

Given this relationship, the quality of a filling and capping machine is very important in terms of determining output product quality. These machines need to be manufactured from strong materials that can resist the heavy manufacturing conditions. Also design should ensure no leak or spill during fillinf and capping process.

Filling and Capping Machine Application

Filling and capping machines used in a wide range of industries including:

Food and Beverage (lactic acid for juices, soft drinks etc.)

Pharmaceutical Industry: Used for producing drugs.

In Cosmetic Industry: Used in manufacturing creams, lotions and other bathing products.

Conclusion

In conclusion, these filling and capping machines are changing the course of production history across a range of different industries. Regardless of the size or shape, filling machines and capping equipment provide numerous benefits above what manual methods can offer-namely speed, accuracy, repeatability and operator safety. Through the utilization of modern technologies including electronic sensors have helped to improved operational efficiency, accuracy and safety such as those coming from Envelope X. The demand for filling and capping machines to streamline production processes continue to increase among food & beverage, pharmaceutical, cosmetics businesses.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ