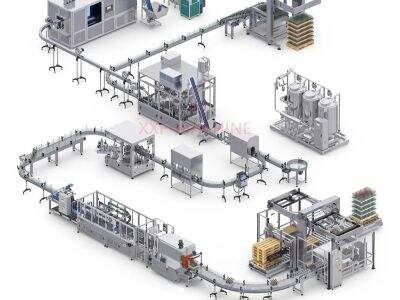

Liquid filling machines are very useful machines used by people for better packaging of various products. They are built to operate quickly while ensuring that everything is done correctly. One manufacturer of such machines is Zhangjiagang Newpeak Machinery. We will discuss how these machines are revolutionizing the packaging process and bringing efficiency to businesses.

How Does a Liquid Filling Machine Work?

You might picture people manually filling bottles and containers with product when you think of packaging. This does take a substantial amount of time and toils the workers out. Just consider how many bottles must be filled every day. However, for everyone involved, when it comes to liquid filling machines, the work is scaled significantly faster and clearer for all attendees. Bottling machines are capable of filling a number of bottles in a short span of time. That means businesses can create and package more items with a quick time frame. This is critical as it allows businesses to expand and fulfill the demands of their customers. That means workers no longer have to perform such hard and draining jobs, which is good for their health and general well-being.

Why Machines Are Accurate

When humans fill a bottle by hand, sometimes they screw it up. They could accidentally fill each bottle with either too little or too much liquid,and it can lead to all sorts of complications. Too little (liquid) in a bottle, and customers may feel shortchanged. If it has too much, it can overflow and make a mess. But with liquid filling machines, these mistakes are virtually eliminated. These liquid filling machine machines are highly precise and ensure that each bottle or container receives precisely identical portions of liquid. Which is super important, because that mean that every product will be equal and customers know what to expect when they make a purchase. It also helps a company keep its reputation for quality.

Helping the Environment

One further and such a great advantage of liquid filling machines is that it helps to lessen the waste. With manual bottle filling, people may spill some liquid and make inappropriate moves; therefore, people waste liquid and containers. This is bad for our planet because it leads to pollution and waste. With liquid filling machines, however, there is comparatively less waste. Their accuracy and efficiency minimize spills and messes. Not only is this good for the planet, it also saves companies money. Waste Reducing companies will use their resources more wisely which will not only result in company's profit but also help clean the environment.

New Technologies

Liquid filling machines kept on improving and enhancing every day. There are always new technologies and innovations that are always coming out. ———One exciting shift is that these machines are more versatile. That means they can fill different shapes of containers with all sorts of liquids. Some machines can fill two distinct liquids into a similar compartment simultaneously. Helper EA : This is extremely beneficial to companies because now they can be more efficient and provide more products for consumers. With these wonderful capabilities, liquid filling machines are sure to impress as technology progresses.

Advantages Of Using Filling Machines

Liquid filling machines are wonderful machines that have a huge impact on the packaging industry. They speed up, improve the accuracy of, and reduce waste in the process. They also help in building better quality and consistent products for end consumers. Zhangjiagang Newpeak Machinery has water filling machines that are needed by any company that packages things. They are one of the best in the business.

If your interest is in staying informed about the latest trends and ideas in the packaging industry, liquid filling machines from Zhangjiagang Newpeak Machinery are the ultimate solution for you. They save time and money, he said, while enhancing their products and protecting the planet.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ